Yesterday was a succes in disguise. Luckily I did not succeed in bending the PVC-pipe. Without the setback I would not had this bright Idea that I found today.

Due to interference the ventilation system has to be situated in the sleeping room. Fresh air comes in above the sleeping room is ducted from port side to starboard and vice verse, descends to the floor and is piped through the aft bulkhead to the lunchroom aft which is a wet room.

After my disasterius pipe-bending experiment I put on my thinking cap and realised that the pipe did not have go through the bulkhead at 90°. In fact it would be much better if it did not. That would reduce the resistence as the airstream did not have to be bent so much. It would also save a bit of wheight as the distance would be shorter and also be far easier to produce. I simply bought a ready made bend and cut it.

Pictures below will illustrate.

Some people say that the diameter of the pipe I use is to small. That it will not allow me to get enough air. I say that the diameter of my nostrils are even finer and the increase of flow is more than linear. For exampel in hemodynamics it is considerd that flow increases with the forth power of the blood vessel. Not directly applicable here but it might be interesting for you readers with an inquiring mind.

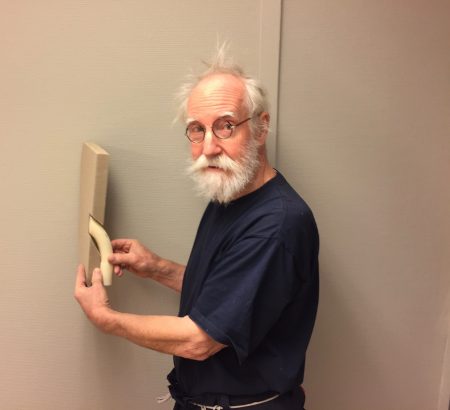

I have also been working on the lunch-box below pictures showing me sandpapering the coaming flat using a large sandpaper on a particle board. Particle boards are flat as there is no tension built into them.

To be continued…

Regards Yrvind.