Here are some pictures showing work on the hatch in the bulkhead.

Taking off shape to make shore the thing fits.

Starting to laminate

Off the mould

It fits and very lucky I can change the gasket with the retainer/drippedge in place saving much work and making it less complicated. Sometimes but not often things goes faster than expected.

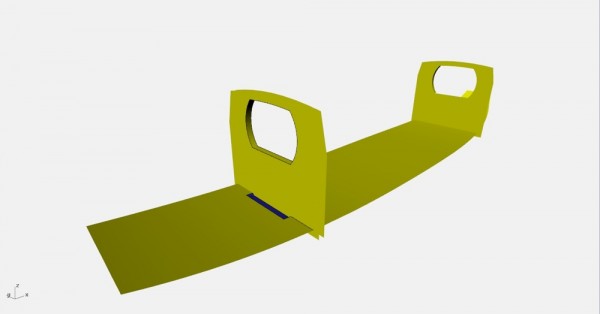

While at it here is the solution for next boat.

BYRÅLÅDSEFFEKTEN

The drawer effect: This is what we engineers call the nuisance when a drawer gets stuck in a chest of drawers and it does not only happen to drawers; it happens to most sliding things that are wider than deep. It is a pain.

To avoid it I made an analyses and it turns out that the solution is surprisingly simple. Drawers that are wider than deep have little guidance and therefore not always move straight but turn. When they turn the short side of the drawer is not any longer parallel with the guiding sides. The drawer takes more space and gets stuck diagonally. The more you pull the worse the drawer gets stuck.

I said to myself: what geometrical figure does not get wider when it’s turned, obviously the circle, by definition. I use part of a circle as can bee seen on the illustration below.

For my hatch I have a second problem. I like to take it out for service. But the guides go al the way around so I have to do a detachable opening in them. On Yrvind Ten its to late to change but on the next boat the “Boat Ideal” it will look like below. Then byrålådseffecten will not give me a problem. Also and very convinient by twisting the hatch 90 degrees it will come clear of its retaining tracks so that I can do service on it

One more screanshott

Today I also written sermon and put it in “BOAT IDEAL” One of the other blogs on my website. You find it at the startpage.

To be continued…

Regards Yrvind.