Changing course has lead people to criticize me because they think I am wasting other people’s time and money. That critic would have been fair if Yrvind Ten had lead to nothing. That is not the case. Valuable knowledge has been gained. Much progress has been made that can be used on other small boats.

Serge Testas, Acrohc Australis was not twelve feet. In the back end she had a big outboard engine and in the forward part a bowsprit. Although these things no doubt could be removed, they were permanent.

This is not against common practice, and it’s the duty of o person trying to brake records to try to stretch the rules and to find loop-holes. Tax layers do that all the time as do people involved in for example Am Cup.

I mention earlier the “Hula” that added unmeasured buoyancy to New Zeeland’s Am Cup boat. On a ten feet boat you could add huge twin buoyant rudders, then locking them making it into an twenty feet trimaran and still sail within the ten feet rule.

Hugo Vilens April Fool was not a healthy boat either. Not before he added an outboard engine could he get offshore. Gerry Spiess and Serge Testa also had to use engines. I believe a small boat should be able to manage with an oar.

I realized that if I did not bend the rule some other designer would, but when I started I did not realize how much the rules could be bend. Size cannot be determined by only length.

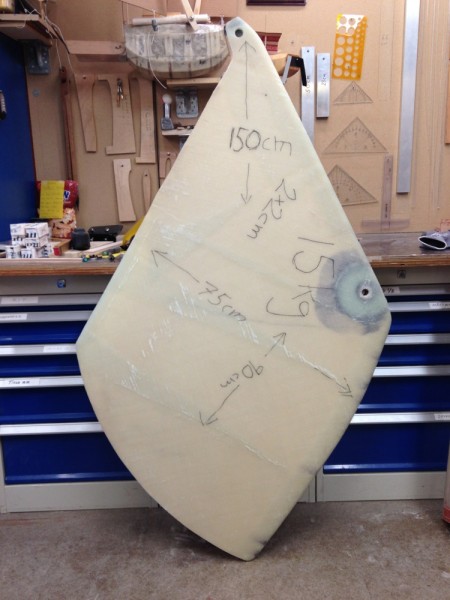

Living with Yrvind Ten for tree years did teach me to think small. She was a stepping-stone to a much smaller and saner boat, Yrvind Ex Lex 4.5 x 1x 0.2 meter displacing 500 kilos a third of Yrvind Ten.

I have talked this over with my sponsors and friends and they are willing to continue to support me. In fact some of them think it’s a very good idea.

Quite a few of my supporters are turning up here in Västervik Saturday 16 of May to help me to laminate the new hull. First I will give a public illustrated talk at Bankens Dag 13:00 in Biostaden together with Captain Thomas Grahn. Everyone is welcome to the talk.

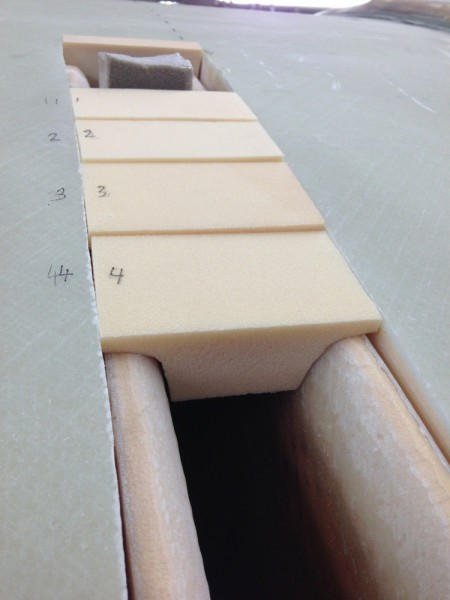

Below the 4 cm thick Divinycell core of Ex Lex ready to recive the NM-epoxy lamination.

To be continued…

Regards Yrvind