I am working with details. One such is trying to bend a PVC-pipe 90° for the ventilation system. To inform myself I search the internet. It did seems that many person was not succesful. Full of confidence I reasoned this does not applay to me becouse I am smarter and I knew a few tricks. First I filled the pipe with sand and copressed it well, then I made a mould to guide the pipe. When the preparations was done I gently put som heat but just on the outside curvature. The result looked very good and I felt justified in being proud of myself as can be seen in the picture below. Click once or twice to enlarge. The lunch-box in the background on my right side with lid on. The hull of Exlex Minor will supply the missing lunch-box side.

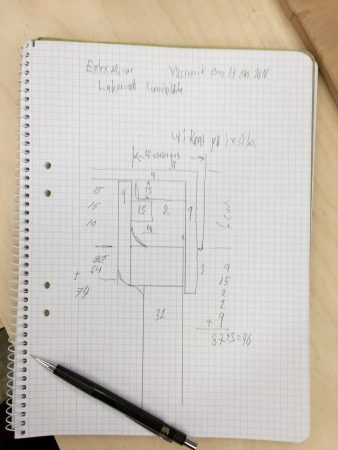

Also more work is being done on the lunch-box. The lunch-box will be situated in the aft part of the boat. Above is a hatch that in breaking seas can let in water. To prevent that water from enter the lunch-box I am making a labyrinth. Below a photo from my sketchbook.

To be continued…

Regards Yrvind