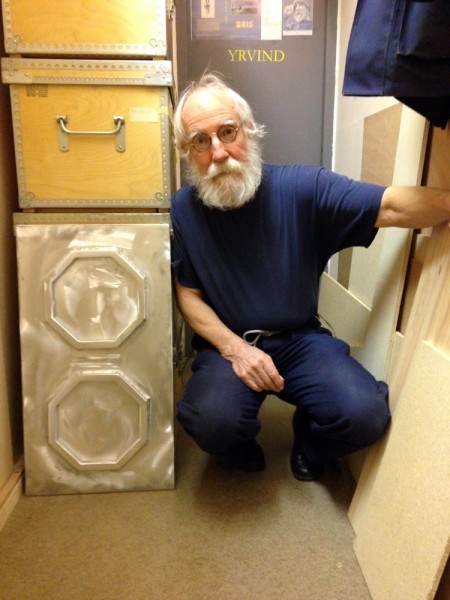

The male mold for the window frames is now done. The female product will hold a 2×3 centimeter EPDM-cell-foam gasket. The windows will be made of tempered glass. That way I get a clear view. Glass transmit heat better than plastic. Therefore I will get a lot of condensation on the windows during wintertime. Some person may at first think that is bad. But humidity will be one of the biggest problems during the cold part of the year. If it gets to the windows I can get rid of it thus making a dryer boat. Dry cold is not really a problem.

Some may think polycarbonate is a good window material because of its high impact strength. It will however crack if exposed to static pressure. Also its very sensitive to solvents. for example just a touch aceton and it will crumble. Try it and you be amazed. In a few seconds its strengths is gone.

One problem with tempered glass is that nickel sulfied cases spantanius fracture in tempered glass. However this is greatly reduced by heat soak test. Statistically there will be about one chance in a millon of it to ockour. If so thanks to the EPDM gaskets I can change a window in a few nimutes. They have a sight thruogh diameter of 22 cm.

To speed up production the mold is for two frames at the time saves on vacum bagging.

A picture below.

To be continued…

Regards Yrvind