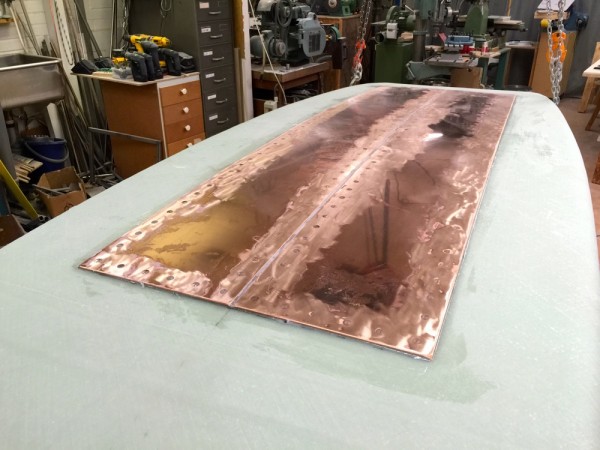

The bronze plate is there to protect the boat when beach landing and act as ballast to give stability.

Phosphor bronze has excellent wear resistance and corrosion resistance. Their spring qualities are also fatigue resistance very good.

I believe in belt and suspenders so in addition to gluing I have screwed the plates with silicon bronze screws. I do not like to use stainless steel below the waterline.

Silicon bronze is just a bit nobler than phosphor bronze and that is as it should be because their surface is smaller.

The scarifying metal will be the phosphor bronze.

Below, part of the galvanic series:

Graphite

Palladium

Platinum

Gold

Silver

Titanium

Stainless steel 316 (passive)

Stainless Steel 304 (passive)

Silicon bronze

Stainless Steel 316 (active)

Monel 400

Phosphor bronze

Admiralty brass

Cupronickel

Molybdenum

Red brass

Brass plating

Yellow brass

Naval brass 464

The screws are set in NM-epoxy. When drilling the holes I pendeled the the drill creating a conical hollow in the Divinycell below the plate and glassfibre into that hollow i injected epoxy.

To be continued…

Regards Yrvind.