.I desire simple, rugged and handy boats. They should weigh less than one ton empty because then I am able to tow them my behind a car, to transport and store them in a container.

With a weigh less then one ton I can drag them up on a beach with the help of a winch. That’s extending my cruising range because.

I have had boats made of wood, steel, aluminum and sandwich composite. Steel is stronger than sandwich-structured composite but I prefer sandwich composite because besides being a structural material it also gives flotation and insulation.

A composite can be made as strong as desired and still be light. To obtain the wanted strength just pick the right fibers, cores and resins.

For decades I have been lucky to be sponsored with epoxy from Nils Malmgren AB, with Divinycell core materials from DIAB and carbon fibers from Svenska Tanso AB. Not only have they been supplying me with the materials but they have also and that is very important given me the necessary technical know how.

There are many varieties of sandwich-structured composites. I have designed one combines, great strength, positive buoyancy and excellent insulation. My formulation differs from more normal ones in that my core is extremely thick for a boat my size. Its core is often 50 mm or 2 inches. If you have a 6 meter long boat with a beam of 1.2 meter and a height of 1 meter the hull surface gives you more than a cubic meter flotation. That volume will float a ton. It is nice to know that your boat cannot sink whatever the circumstances.

Yes, a thousand times and more, people have been telling me that, that was what they said about the Titanic. Still there are millions of surfboards and similar devices around the world that do not sink and cannot sink.

As a Swede I spend much of my sailing time at high latitudes. Today my boats have good insulation. This has not always been so. I have learnt that it is important to avoid condensation because it leads to molds. Molds are no good, they present health hazards, gives allergic reactions and cause respiratory problems. They also give of a bad smell. Molds turn a nice boat into an unpleasant one.

In May 1980 I was sailing south from Mar del Plata, Argentina towards Cape Horn, I had an aluminum boat. I had insulated my boat as best as I could but there were still plenty of unavoidable thermal bridges at odd places where cold leaked into the boat and caused condensation points. Such places were around windows and hatches.

After a week at sea I saw the first green slimy things. It was so cold that I was in sleeping bag most of the time with a cap on my head and gloves on my hands. The molds soon started to grow on my sleeping bag. After a month in those conditions the bravest of them had even invaded my beard.

There was no heating in the boat. The cabin temperature was about 7° centigrade. I tried to get rid of the condensation and the molds but they were growing all the time. In the end I had to ignore them as best as I could. After 40 days I docked and could clean the boat and myself.

In contrast 1989 I sailed from Ireland to Newfoundland. That part of the Northern North Atlantic Ocean must be one of the world’s foggiest places.

Outside humidity and dampness was everywhere.

In my cabin it was warm cozy and snug. That was due to the 50 mm Divinycell and uninsulated widows that were acting like condensation plates absorbing the dampness drying the air. Even the salt was enjoying the dry atmosphere and was happily running smoothly without any lumps. Compared to the aluminum boat the difference was like day and night.

An alternative is to have a heating system burning all the time. I do not consider that a simple cheap alternative, nor is it environmentally friendly.

In September 1962 I sailed into Kopenhagen with Blekingsekan. I tied her up in Christianshavns kanal outside an old Baltic Trader. Most of my time I spent in libraries studying boatbulding and mathematics. When the last library closed at 22:00 I went to a cheap café to seek more information and advice from the city’s many university students.

Usually I was not back to my boat before one or two a clock in the morning.

One December night when it had gotten very cold and damp in my uninsulated boat I fired up my kerosene stove to get some heat in my cabin. A curious thing happened. My kerosene lamp started to dim. I turned up the wick but within a minute it started to dim again. I checked the reservoir I had just filled up.

It was full.

This was mighty strange.

Why did my lamp not work?

Conscious or unconscious I must have opened the cabin door a bit. Fresh air entered the cabin and my lamp started to shine brightly.

A lesson: If you burn fuel for heat bee sure to supply oxygen.

Ten years passed. September 1972 I was on my way south through the Danish islands in my first Bris, a wooden boat. The topsides and deck was 10 mm plywood. The nights were cold and the condensation so bad that it started dripping on me. To cure it I covered the ceiling with 30 mm Styrofoam. It worked fine. Later in the spring when I trailed her back to Sweden from Holland to fix the centerboard and rigging I also did a better job on the insulation.

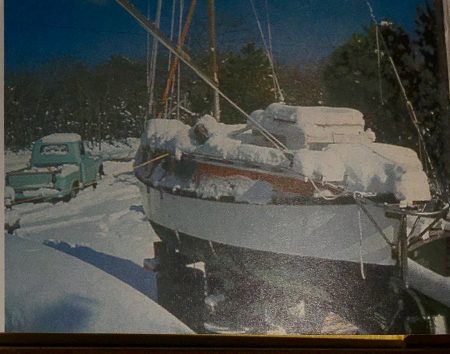

The winter 1975 – 76 I worked with trimaran designer Dick Newick on Martha’s Vineyard. During the winter I lived in Bris on Daffy Ducks boatyard where we built the Val trimarans. At a thrift shop on the island I had bought a small bread toaster for 1 dollar. It kept me warm the whole winter despite some cold northerly winds

An insulated plywood boat is an alternative to sandwich-structured composite, but it is not nearly as good. The composite boat has an inside that is much easier to keep clean, as there are no crevices and hollow places that hide cockroaches’ bugs and molds. Every surface on my boat is accessible to clean.

Besides that and this can be very important the composite boat is far stronger than a wooden one. It is good to have extra strength for the unexpected.

1979 I was navigating Brittany’s inland waterways in Amfibie – Bris together with Olga. We had left Redon and were on our way to La Gacilly. I had been sculling Bris up the Aff, a small river. We had tied up at the dock at Glenac in an etang a small pond.

It was the end of March and we were the only boat at the long dock.

Olga had started to prepare the evening meal when we saw a canal boat, a small steel barge entering the etang from the other side. Everything happened very slowly until in the end when everything happened fast and all at once.

The barge was slowly coming closer across the pond and heading towards us despite all the empty places on the dock. In Sweden people are keeping their distances. We do not so much mix with strangers. Well I thought, now we are in France and here people are more sociable. The barge was headed straight for us. They did not slow down. They rammed us broadside on.

A steel barge even if it is not big coming with the moderate speed of 3 knots will give a very big impact; especially as our case we had the dock at our other side of us acting as an anvil. There was a big bang as.

Shaken I rushed up on deck. On deck of the barge there were two French couple “ Excuse nous, nous sommes debutants” I heard they said unison. Excuse us we are beginners.

A good enough explanation.

Any ordinary boat would have sunk, not so Bris, her rubrail got a bit deformed but that what they are there for.

I like the French, but they sure are a bit odd. Another time now in Paris, 1964 I think it was, I was driving my Volkswagen when I had an accident at slow speed. This time the driver came out and said, “ Excuse me I was looking at my wife”.

On two other occasions during the same voyage Amfibie – Bris was unexpectedly hit in different ways but not as hard as the first time. It is good to have a strong boat.

Other small boats do not have 50 mm closed foam cores. At most they may have 10 mm. Strength increases very rapidly with thickness. When a boat gets hit the outer laminate gets compressed and the inner one is stretched, compression and tension. In the middle there is the neutral axis.

If a boat has a hull that is 5 times as thick as another boat it takes a force 5 times as big to break her inner laminate. The impact is distributed over an area of inner laminate that is 25 times as big. To increase my boats strength even more I use carbon fibers in NM-epoxy for the inner laminate, the skin that takes up the tension. Also the volume of the Divinycel core that takes up much of the impact energy is 125 as big as the thinner composite.

The materials I use are all expensive but a boat with a displacement of 600 kilos uses less than 5 % of the amount of the material that todays cruising boats in the 40 to 50 feet range uses.

In conclusion, a small boat built with high quality materials is much cheaper than a big boat built of cheap stuff. Besides other expenses on a small boat is also small.

Please support my project by donations

Regards Yrvind