The lug sail is not attached to the mast by a track, only by the halyard. The pull varies at least 270 degrees. To utilised all of the mast the Ex Lex halyard comes out at the top of the mast at the center.

The diameter of the Dynema halyard is 6 mm the hole is 10 mm diameter.

Previus experience with POM aka acetal and Delrin has shown that it does not hold up to extensive wear. I therefore chose bronse even though it heavier.

Below are some pictures.

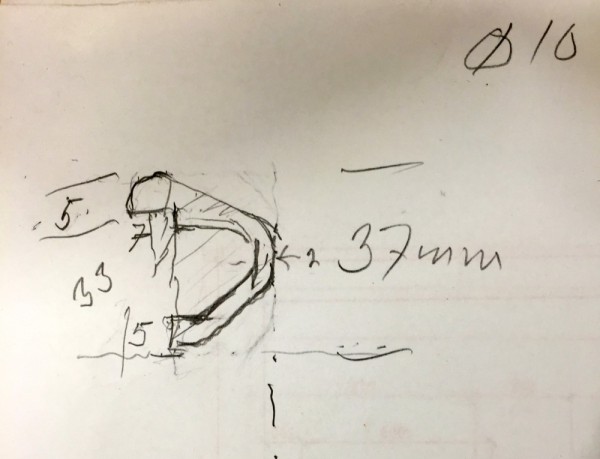

The first sketch.

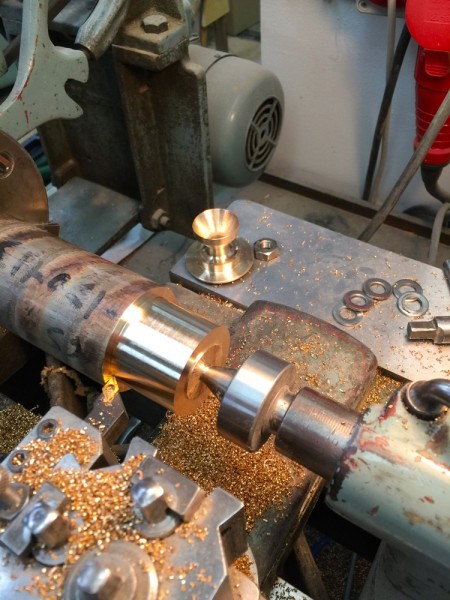

In the lathe.

Ready to be cut.

The finished product. Its conical on the outside as well to save a bit of weight at the top of the mast.

Ready to be tested with the halyard. The mast is the bottom part of Eurupe Dingy masts, donated by Marström.

I do not have inside halyard. A small piece of bent titanieum reduces wear on the carbonfibre.

Silicon rubber is inserted to create a epoxy tunnel.

The mast are standing upside down. Me injecting epoxy above the fitting, embedding it.

Close up.

After the the NM-epoxy has set the silicon rubber is pulled out and leaves a nice tunnel for the halyard.

This way of raising the sail takes more force than using a system with a pulley, because of friction, but the sails and spares are so small that its OK.

On the other hand its creates less compression on the mast (becouse of friction) and it has no moving parts and is omnidirectional so not much should go wrong.

To be continued…

Regards Yrvind.