Production boats are optimized for windward work. Therefore they have weather helm. Cruising boats spend a lot of their time going downwind. A trade wind passage or a voyage in high latitude west wind belts in a boat that has weather helm is not optimal. I designed Ex Lex with leeboard so that I can get lee helm by lifting them up. Leeboards leave the boats bottom nice and clean, no centerboard case that creates turbulence. There is no better lateral arrangement than leeboard for going downwind.

External forces tend to deviate at boat from its course. The winds strength and direction keeps changing therefore the sailor has to adjust sail area and rudder angle. That work often exposes the sailor to the elements at awkward times.

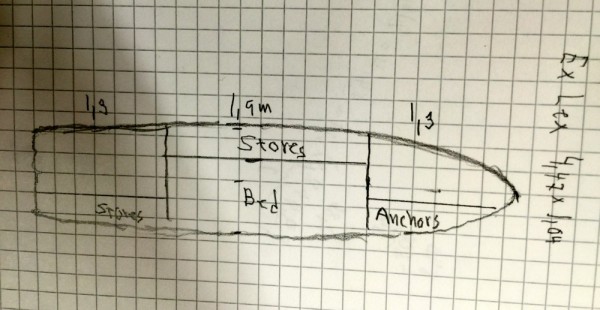

To make it easier for me I have a dry and cozy sleeping room in the middle of my yacht enclosed by waterproof bulkheads. At either end there is a control area.

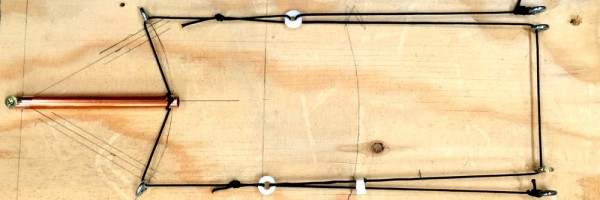

In the back a deckhouse, the forward end a smaller deckhouse. My boat is divided into three parts. From everywhere I like to adjust the rudders therefore the tiller lines run a circuit around the boat. The top line for the starboard rudder the bottom line for the port rudder.

The rudders can be moved independently of each other. To move both rudders I grab both lines.

If I like to slow down the boat, for example running before a gale or handling sails I move their aft end out letting them form a V. I light wind I tilt the windward rudder up to reduce resistance.

The tiller lines comes into the boat through a pipe under the aft deck. The line is sealed with piston cups that no water may enter the boat that way. To keep the pipe and tiller short a block and tackle is used.

Handling the rigging and leeboard is done from the forward hatch going downwind even if my destination is to windward; the reason less water is coming onboard.

To orient myself to the sea there are some small oval windows, 15×6 cm, in the forward deckhouse.

I like to be able to adjust the sheets from either deckhouse. To make me able to do that the sheet is in an endless loop with three attachment points, the sail and the two deckhouses.

The masts are short 1.8 meter and 2.3 meter above deck. In strong winds I dowse the big sail and place it and the mast on deck.

The masts are side by side. Using one mast on the lee side makes the boat more weatherly. Using one mast on the windward side gives lee helm.

Running with two sails wing a wing the sails can be let out more than 90 degrees making at very stable configuration. Balanced lugsails are only attached to the mast at the top and they do not need a boom vang as the dawn haul is aft the fore end of the boom.

The rudders are attached to the bathing platform that extends the waterline and gives the rudders more momentum.

Below are a few photos to illustrate my text.

The endless loop runs thrugh a single block in the boom, a dubble block on the deck – the sheeting point then on end runs forward to a cleat at the forward deckhaus, the other part back to another cleat at the big deckhous. Then the loop connects the cleats.

The loop seen from the aft deckhouse.

The loop seen from the forward deckhouse.

The loop seen from the port side

Last picture of the loop. I hope you get the idea.

Above the principal of the inside loop that goes all around the boat. A singel block at each side does the gearing. Rope jammers – not shown – will fix the rudders in the desired position. I will give enough friction in the system that the rudders do not easily move without my intention even when the jammers are released, when I move from one position to an other.

The rudders. The control lines goes into pipes under the aft deck, not shown here. The are sealed with leather cups to keep out water. The boarding ladder is in the water.

The rudders in the braking position to be used as a drouge.

In the above picture the two deckhouses can be seen. The small windows on the forward deckhous are indicated.

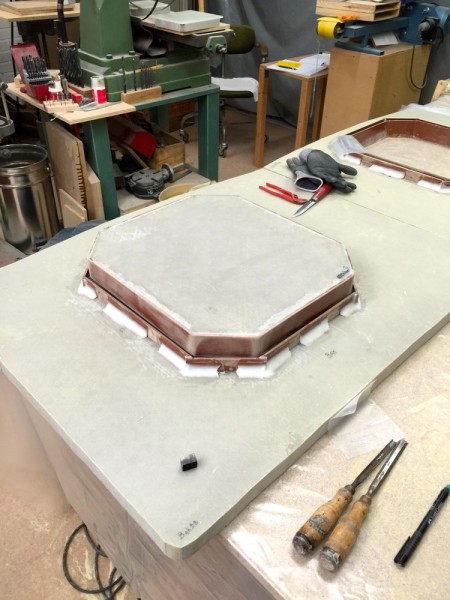

Above the forward deckhous in full scale. The windows gives me an excellent vieuw allowing me to orient the boat nicely before open the hatch. Saving me from useless bailing.

To be continued…

Regards Yrvind.