A PLATFORM TO TEST MY IDEAS ON

My appendix is already gone so in preparation for my coming long voyage it was only logical to pull out all my teeth except the front ones, which I think, in an emergency, I can handle myself. It took some convincing before the dentist was willing to do it. After one and a half hour I left the office bleeding in all the four corners of my moth.

When the anesthetic stopped I was not so shore that I had been so smart. During the first three weeks the pain kept me awake. To keep my mind occupied I started to write on a book: A dyslectics venturesome voyage. The manuscript is now sent to a publisher

For four months I have been writing twelve hours a day. During all that time I did not go to my workshop.

When I was out running, when I was eating and before falling asleep I did however think of Yrvind Ten finding out new smart thing and reflecting on the ones already done.

As Clausewitz pointed out, few plans survive the first contact with the enemy. I realized that all might not work as smoothly as I have envisaged. I have therefore decided to test the rig, the rudders and the new steering arrangement among other things and having some fun at the same time and acquire the necessary seamanship to proper handle the equipment.

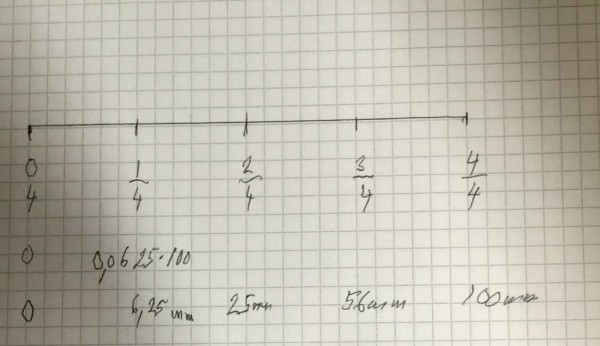

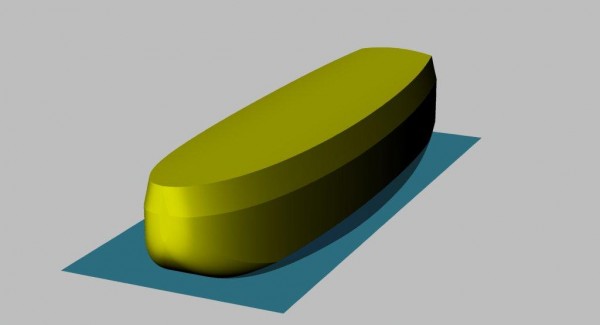

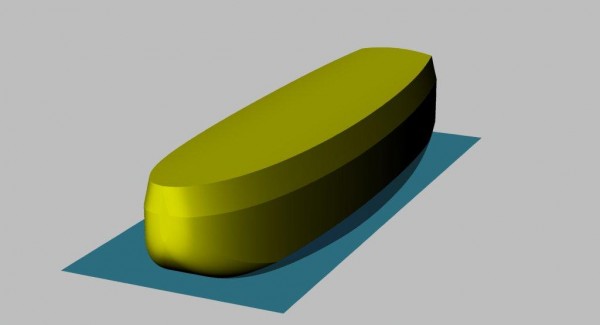

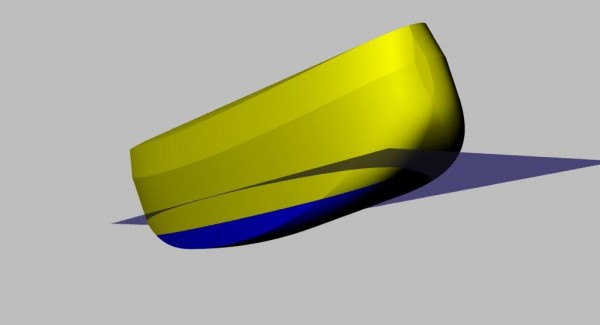

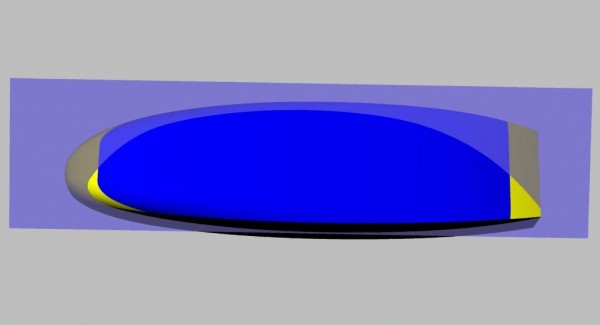

To enable me to do that I will build a 3/4 version on the same lines as the 5,4 meter Boat Ideal. She will be a quarter of Yrvind Tens displacement

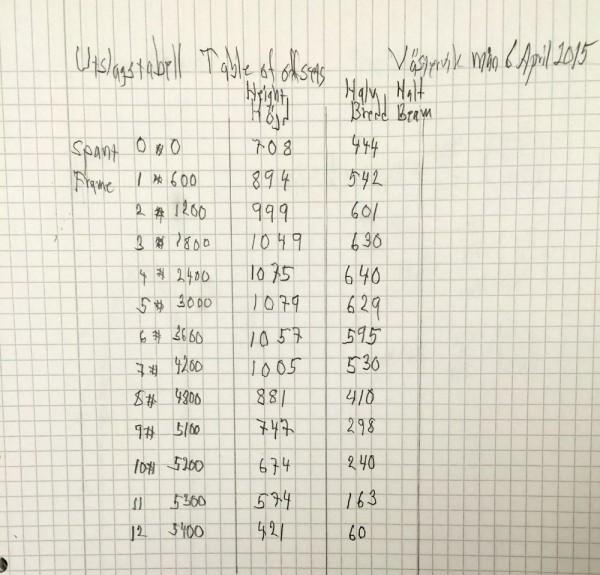

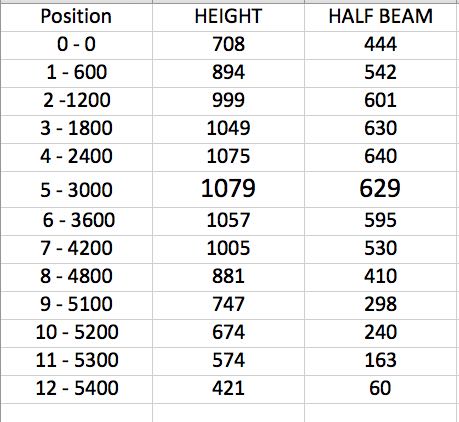

PARTICULARS OF THE YACHT:

Lenght 4.05 m or 13 feet 3 inches

Beam 1.05 m or 3 feet 5 inches

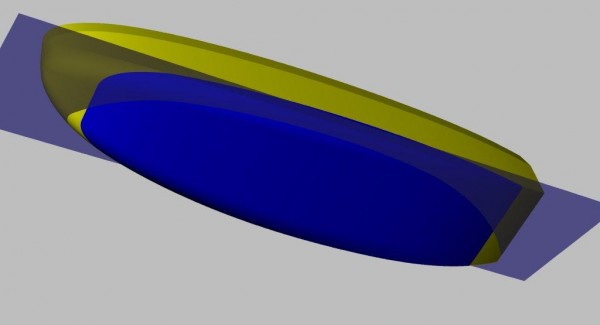

Draft 19 cm or 7 inches

Sail area 8 sq meter or 86 sq ft.

Displacement 422 Kilo or 930 pounds.

My rough weather hatch will be in fore end of the boat next to the side by side masts. There I will handle the sails. Going to windward that’s the wettest part of the boat. Therefore I will be running as I am used to. Now with twin rudders that I can individually adjust I can angle them outward creating a variable breaking force that will keep the transom to windward. Adjusting the rudders is done by a rope running the periphery inside the hull.

To avoid water and dampness enter the inside the ropes passes through the hull via cylinders. The part of the rope that is inside the cylinder will have piston rings or rather rubber washers to keep the water on the outside.

There is an aft hatch in bedroom. Normally it will not be opened in rough weather because if the bedding gets wet with salt water it will not dry. To overcome that disadvantage I am planning to learn to sleep without a matrass, then I can just toss my sleeping bag in a locker and no harm will be done if water enters. I will see if the years has made me soft.

I do not know what kind of problems that will pop up, therefore the testing.

What does XLX stand for? If a bureaucrat asks I will say Extra Large Experimental, if a friend asks I will say that it is Medieval Latin meaning, ex lex, bound by no law. I think an experimental boat deserves a bit of freedom early in her life.

The mast stands side by side. She has leeboards and twin rudders. She is built of 40 mm Divinycell laminated with NM-epoxy.

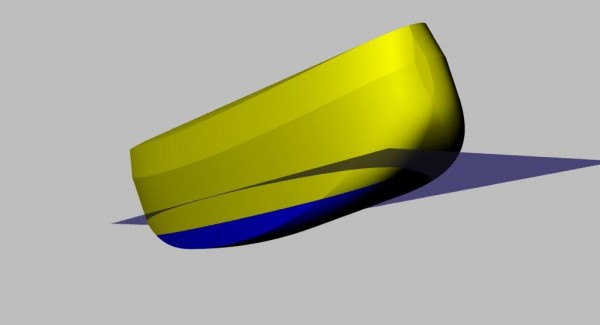

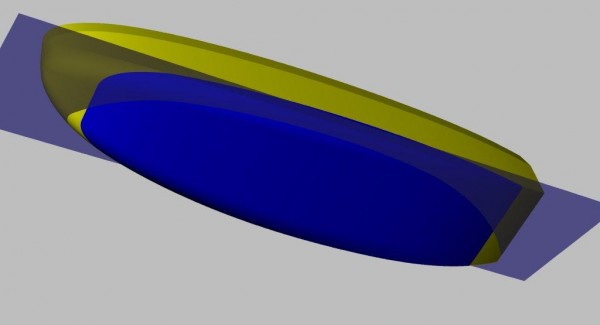

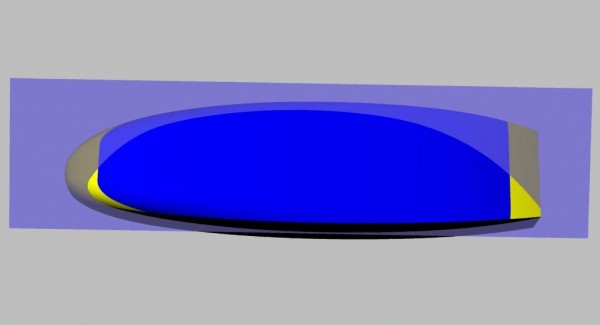

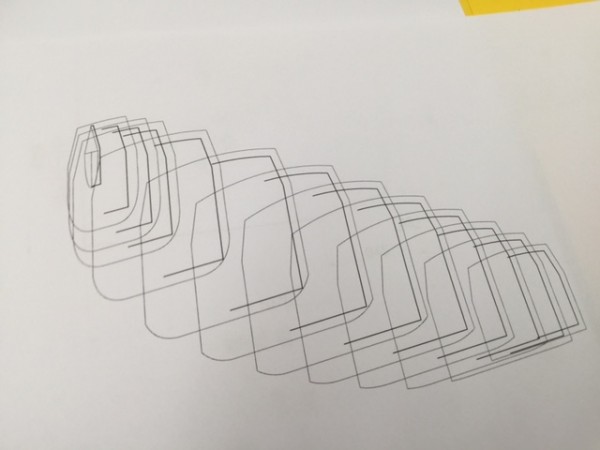

Below are some illustrations.

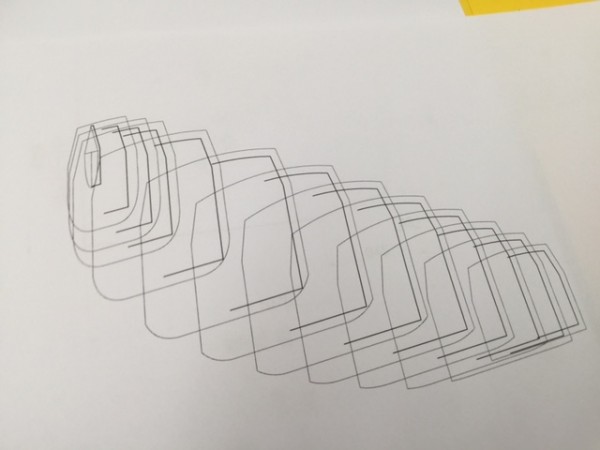

Above are the sections. The rounded lines are outside, the straight lines are lines from the inside of the hull.

Becouse the Divinycell is 40 mm thick I can shape her before laminating, thus getting a softchine hull on the outside and a hardchine one the inside. Where I take away to muck material I will compensate by gluing wedges on the inside.

The Divinycell gives flotation and insulation.

To be continued…

Regards Yrvind.

Like this:

Like Loading...