Here is some more pictures of the lamination.

To be continued…

Regards Yrvind.

Welcome to Yrvind´s website: small boat designer, builder, sailor & writer

Here is some more pictures of the lamination.

To be continued…

Regards Yrvind.

Today my friends have helped me to laminate Exlex Minor with NM-epoxy. Everything went very well. Good epoxy and very competent friends. An important step towards new adventures.

Some of my friends have helped me for decades. They have much experience and we all agreed that this was the best laminate ever of all the ones we had done. Also the best shape of all my boats, a good omen for coming voyages.

I will try to get more pictures from my friends who took pictures during the laminate.

To be continued…

Regards Yrvind.

Now nearly all preparations for the lamination is done.

Today Petter helpt me to cut the glassfiber. I had not so much glass fiber as I thought. Had I had more glassfiber I would have cut more for more layers. Still this will be fine, more than enough strong by most judges and the boat will be a bit lighter and that is important.

The day of the September equinox Sunday 23 of September at 9 AM we, my friends and me, will start the lamination of Exlex Minor. It is a big moment, much depends on the succesfull outcome and I am a bit nerveus although I could not wish for a better team.

To be continued…

Regards Yrvind

Are you a group of persons interested in small ocean going boats like Exlex Minor. Welcome for a guided tour. The fee is € 700 poor groups gets an price reduction. If you are rich you have to pay more. The money goes to the research and development of Exlex Minor.

Regards Yrvind

September 12 2018

More of the NM-Epoxy for Exlex Minor from Nils Malmgren Ytterby has arrivied. My plan is to make a very strong bottom on the boat. It is good for handling the boat on land and I an emergency gives me the option run the Exlex up on a beach. The only place on Exlex where weight is advatageus is on the bottom.

Sunday morning 23 of September me and my friends plan to start to laminate the outside of the hull.

Most of the preparations are now done so there is not much more I now can do except relax a bit before the lamination is done. When done the boat will be turned right side up and lamination of the inside commence and the bulkheads.

To be continued…

Regards Yrvind

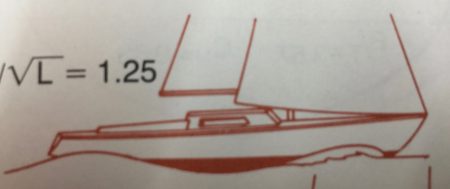

Today racing yachts strives for a wave piercing bow. To slice through a wave instead of having to fight your way through it sounds like what a strong man should do.

Racing yacht and cruising yachts are different kind of boats. A racing boat is often built light and driven hard to windward a cruising boat is heavier and the sailing is more relaxt, its course is mostly downwind.

A cruising boats max speed or hull speed happens when the bow wave and the stern wave join each other and become one, creating a trough so deep that the boat is captured in it and can only travel as fast as the wave. The speed of the wave is the square root of the wavelength times a constant. Thus the longer between the bow wave and the stern wave the faster the boat can sail. Accordingly the earlier a boat can create a bow wave the faster she can sail. That’s why yacht designers give fast boats, boats that travel at a high Froude number a high prismatic coefficient – the prismatic coefficient is how many % of the underwater hull is left after you shaped a prism with the boats midsection and its waterline length. A high prismatic means full end, the opposite of wave piercing. Common numbers for sailing yachts is 0.54 % powerful powerboats more towards 0.7 %

The ocean sailing yacht may not have such a high average speed but out on the ocean there are big waves and in the trough, sailing downwind, there is a counter current often 2 to 3 knots fast if you add that speed to the average speed you are in a high Froude number speed range and need a high prismatic not wave piercing bow.

One more thing sailing fast down a wave and meeting a counter current is to ask for a broach. A spoon bow reduces the risk of broaching.

Further a spoon bow increases a boats initial stability as it makes the boat wider in the bow than the wave piercing bow and it’s the beam integrated over the length of the boat that is the initial stability.

Below two illustrations

To be continued…

Regards Yrvind

Yesterday I gloud the last piece of Divinycell on the hull of Exlex Minor.

Today I have been shaping her. There is more shaping to be done using the long board. The though Divinycell 350 kilo per kubic meter is hard to form but with patience I get there.

Below are three pictures.

Next step is to laminate her outside. For that I need help of friends. I need 6 persons minimum 12 would be better. because there will be many layers of glass. Being a beach landing craft she needs a strong bottom.

Hard to say wich week end the lamination will occur so dear viewer be patient.

To be continued…

Regards Yrvind

All the pieces that connect the bottom and the hull side are now in place.

Luckily I was getting better and better att fitting the pieces becouse cutting them out got more and more difficult as I was getting closer to the bow. Piece number 6 and 7 was the most difficult because the the chine was bending inwards and downwards at the same time.

To be continued…

Regards Yrvind

The bottom pieces are now in place. Only a few connecting pieces are missing. However I have to take care because there is still some tension in the side pieces.

To be continued…

Regards Yrvind