During the time I was building the mock up of Exlex I had plenty of time to think. At first things went well but as time passed I realised that not only there would be an awful lot of gluing but that that would make the boat more heavy and decrease insulation.

An mock up is a very good thing. Having the boat on even keel and being able to move around in her made me realise that I could do very fine with much less boat. With much less boat I could also reduce the sail area from 12 square meter to 9. Three sails on three masts.

2011 I sailed a small boat 4.8 long with a beam of 1.3 meter to Martinique. Matt Layden had helped me to design her. She had chinerunners.

Now I had the idea of transforming her into a double ender as I had gotten them into my head.

Mentaly I mirrored her for part in her maximum beam. I made her bow a bit more boyant for big waves and to increase the wave creating lenght.

In the early sixties I spent a lot of time studiing mathematics. I learnt about transformations conformal mapping in the complex plane and such thing even if I did far from understand it fully I found it fascinating.

I also read On Growth and Form is a book by the Scottish mathematical biologist D’Archy Wentworth Thompson on transformation in nature.

I relised that almost anything caneasily be transformed.

So Exlex the Canoe Cruiser changed form with the help of the boat I sailed to Martininique.

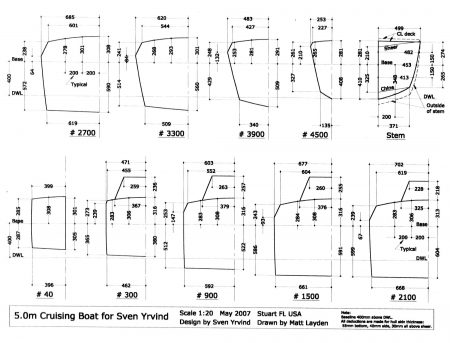

Below are some illustrations.

I will use frame

Stem, 450, 390, 330, 270, 210, 210, 210, 270, 330, 390, 450, stem. Spacing them 60 centimeters. Horizontal numbers will be reduced by multiplication by 0.8 to get a narrower boat. Vertical numbers are the same for the hull. Modifiying a bit as it pleases my eye.

Six beam long double ended plywood boat 7.2 X 1.2 are not common but, 1975 in New England I saw an International 110 designed 1939 – the same year I was born – by Ray Hunt. It was quite a succes and is still racing. My boat will not be a daysailer. It will have balanced lug rig and its lateral area will consists of near vertical, ballasted chinerunners complemented by a bow centerbord as on my Amphibie Bris of 4.8 long that I sailed to Newfoundland 1989. The two forward masts will be side by side as in my 2018 sail to Madeira. It was an excellent rig.

https://en.wikipedia.org/wiki/International_110

If you enjoy my site please support by a donation.

To be continued…

Regards Yrvind.