Today, besides running I have been using the long board on Exlex. The result is hardly noticebel but I include a photo anywhy.

Also I have been on the phone trying to organize the lamination.

To be continued…

Regards Yrvind

Welcome to Yrvind´s website: small boat designer, builder, sailor & writer

Yesterday I gloud the last piece of Divinycell on the hull of Exlex Minor.

Today I have been shaping her. There is more shaping to be done using the long board. The though Divinycell 350 kilo per kubic meter is hard to form but with patience I get there.

Below are three pictures.

Next step is to laminate her outside. For that I need help of friends. I need 6 persons minimum 12 would be better. because there will be many layers of glass. Being a beach landing craft she needs a strong bottom.

Hard to say wich week end the lamination will occur so dear viewer be patient.

To be continued…

Regards Yrvind

All the pieces that connect the bottom and the hull side are now in place.

Luckily I was getting better and better att fitting the pieces becouse cutting them out got more and more difficult as I was getting closer to the bow. Piece number 6 and 7 was the most difficult because the the chine was bending inwards and downwards at the same time.

To be continued…

Regards Yrvind

The bottom pieces are now in place. Only a few connecting pieces are missing. However I have to take care because there is still some tension in the side pieces.

To be continued…

Regards Yrvind

Today more pieces has been added and the end in form of a nicely shaped bow can be imaged.

To be continued…

Regards Yrvind

Today, besides doing two bottompieces I have started to glue the connecting bevel pieces.

Below are three pictures. Click once or twice to enlarge.

To be continued…

Regards Yrvind.

Now I am getting to the forward part av the boat leaving the square aft section behind and going to start the compound curvature. I have decided to do that by connecting the sides and the bottom with bevels of incresing length.

Leaving the sides as guides I shape the bottom part by taking the average of the bottom of the male mould.

Below are some pictures.

To be continued…

Regards Yrvind.

Today I have with the help of Håkan added two sheets of Divinycell on the bottom. I am now getting close to the more complex bow with its compound shaped curvature. I am not really shore how to solve that problem but I cross that bridge when I come to it.

Below two pictures from today.

Please continue to supported my project.

To be continued…

Regards Yrvind.

Reluctantly I now realise that due to weight, time and money restrictions I have limit myself on experimenting with Exlex Minor. The idea of twin rudders and bilgeboards has to be put on hold for later boats.

There will be one central rudder. That makes it easy to find a place for the sculling oar and also make an rudder indicator. The transom will not be so crowded.

As for lateral resistannce there will be a offset centerboard if my gentle reader can accept such an oxymoron, or should I call it single bilgeboard?

In the sixties a book on seamanship was published that made a lot of impact. I am speaking of Adlard Coles “Heavy Weather at Sea”. Two schools of riding out a storm was discussed. On one hand lying to sea anchor or drouge or the Moitessier way influenced by Vito Dumas, running free. Myself, I was influenced by the running free idea. My intended twin rudders used as brakes was a middle way. But I reluctantly realised that due to money, time and weight restrictions I have to do without the twin rudder brake idea.

A small boat is not as valnurable as a big one. It will not so easily get hurt if capsized or pitchpooled. Also in my upcoming attempt to round Cape Horn in Exlex Minor I now have a spoon bow and a very high prismatic coefficient. I think they will help her not to dig down and broach running down a big wave.

Big boats have problems with self-steering. My side by side rigg should make Exlex Minor easy to self-steer. Most of my ocean passages have been done without self-steering gear or sheet to tiller arangements.

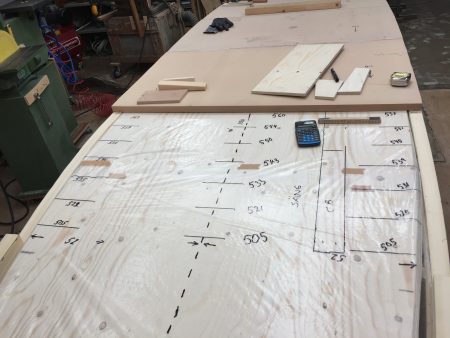

Below are some pictures showing where the centerboard will be placed.

The rectangle marked CB indicate the place of the centerboard.

The CB position viuwed fram aft.

The CB position viuwed from bow.

To be continued…

Regards Yrvind.

Exlex Minor will sometimes, after an ocean crossing be used as a beach landing craft. She will also be transported on trailers. This calls for a strong bottom.

To get a very strong bottom on a sandwich construction you need a tough core. Diab has supplied such a core. It has military specifications and is used for submarines among other thing. Yacht 40 – 50 -60 feet use a core of a density of about 80 kilo per cubic metre. The core I have chosen has a density of 350 kilos per cubic metre and is very strong, roughly strong in proportion to its density. Each sheet is tested.

I have now started to do the bottom. The core is 27 mm thick. I cannot bend the sheets. They are to stiff. Therefore I have cut them into smaller pieces and I am cross planking her bottom. That way I can give her the desired lungutudinal curvature.

Below some pictures.

Abowe: The first three cross planks.

A closer look. The circle is where the test piece has been taken. First I got angry at all those holes, but when Anders at Diab explain the purpose I got proud that such care had been taken to produce the material to my boat. No haphazard manners here.

65 centimeters of the lenght of the boats bottom has been done today.

I have also added 10 fluoerscent tube to get more light. Winter is coming. Being in a well lit workshop brings happiness.

In the bow end of the boat I have with the help of a laser marked the center.

To be continued…

Regards Yrvind.