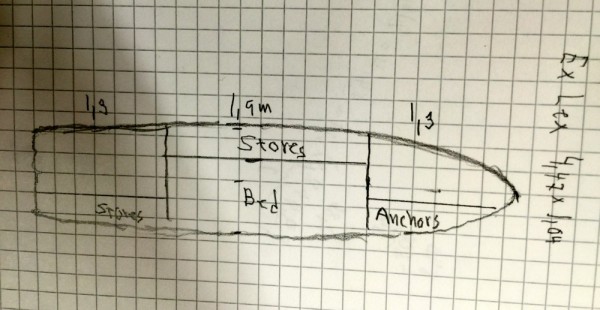

I have made progress on the bulkhead hatches.

I am using “tufnol” an early composite material of phenolic resin reinforced with cotton fibres to get edges that will put pressure on on the EPDM cell rubber gasket.

To get an overlapp I am adding 5 mm Divinycell to the bulkhead frame.

Gluing them

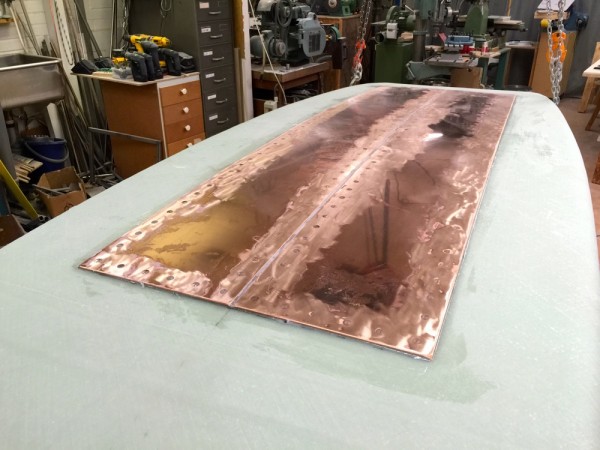

Now comes the outside pieces holding the gascet. Instead of gluing the EPDM I am squising it in position. That makes it very easy to replace them, if need should be at sea as EPDM is difficult to glue, but you have to work within a 0.5 mm margin to get it good. The gasket is 15×20 mm. The gap is 14.5 mm. To get that pricision I am using spacers.

Gasket in place.

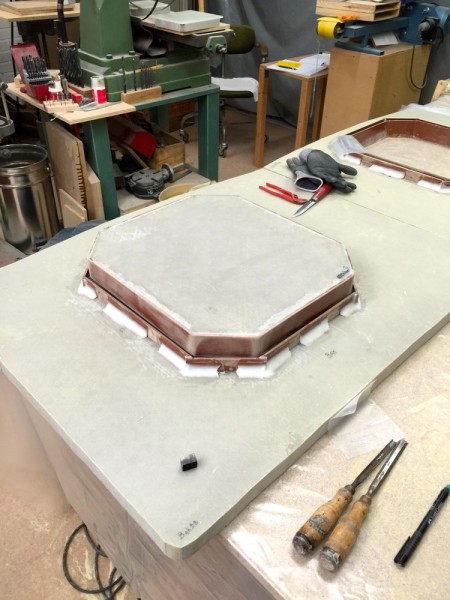

The hatch fits.

Detail.

Next problem, working out a system to get enough pressure on the gasket to make the hatches waterprof.

I am quite pleased with this idea. Its fast and gives good pressure. Top view.

Side viuw. I am using a over center fastener and rollers to get even forces in the dynema rope.

To be continued…

Regards Yrvind.