Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Got wheels and safety belt

The project have now gone into finishing details

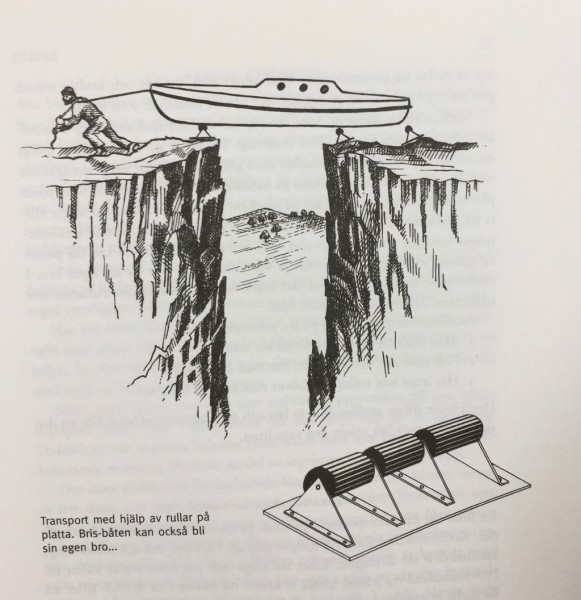

To get the boat out of the rather cramped workshop it has to be rolled.

I have made an axis and put 4 wheels on her. I made the wheels out of hard polyurethan rubber subblaied by UW-elast Mariestad, the bronce bearings is from Lagermetall Örebro.

When the going is good and the ground is flat the wheels are attached to the boat. When on a beach with soft sand or big boulders or in rocky mountains where the terrain is rough the wheels is put on the ground and the boats bottom is supplying the smouth surface.

In fact the boat can even become its own bridge. Illustration Martin Mörck from my book: Konstruktören 2003

Me strapped down in my bunk. I use a diameter 12 cm fender as pillow.

Viuw from the bow

To be continued…

Regards Yrvind.

I have added a safety belt for stormy weather.

ELECTRICITY

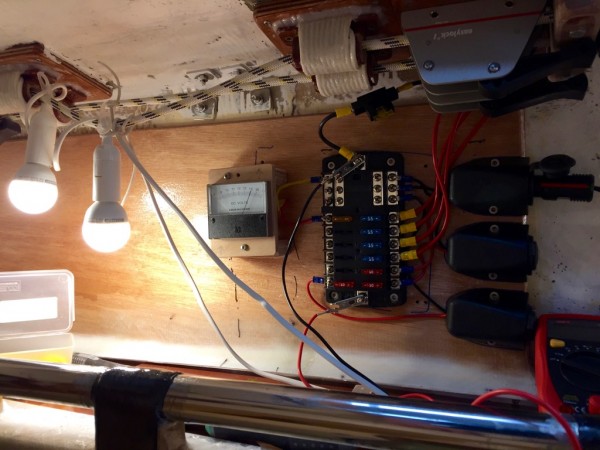

I have made progress with electricity

What is left is the solar panels and their regulators.

The VHF radio and AIS I will install hopefully with professionaell help coming winter.

Below is a picture of the panel.

the 4 red cables coming in is from the 4 batteries. By disconnecting respectivly fuse I can check the status of each battery.

The lines at top is stearing cables and jammers to the port rudder.

There is not a whole lot of electrucity. I will have a fan to cool me when crossing the equator becouse in a small boat the temperature at noon can rise to 35 degrees C

To be continued…

Regards Yrvind

THE BATTERIES ARE INSTALLED

The four 55 Amp gel betteries are now installed.

I have wrapped them in rubber with adhesive that the rubber does not slip. The will work as schock absorber.

Below a picture:

Its a real close fit in all directions. The batteries are heavy still I had to press on them to get them down. I do not think I can get them out again. Hopefully I never need to.

Thera are four of them in two compartments. On top is more rubber as schock absorbers when capsizing.

The lid is screved down with 11 M6 screws

The lead is now also stowed in its compartment.

To be continued…

Regards Yrvind

TWO MORE PICTURES AND A VIDEO

I start to see the end.

What is missing is painting and electricity, two ssubjects I know very little about.

The rudders and the Yuloh.

Me and the leeboard.

Here is a link to a 2 and a half minute video about my coming voyage

https://www.youtube.com/watch?v=Q6LVzOpMzqA

To be continued…

Regards Yrvind

REEFING

EXCUSES

There are two reasons for why i have not been active on the blog lately.

One reason is that I am writing a booklet about building the boat Exlex and the preparation for my planned sail to the non-stop sail to the antipode.

Work on the booklet might take two more months. Its in swedish so start practising.

The other reason is that work now is much about details, not very exciting.

Below are two some pictures.

The lead is now trimmed to fit very nicely into its box. I have painted in NM-epoxy to as lead is poisoness. That way its also cleaner.

Here its in the boat. The handles are temporary to help lift them out. I had to lift them in and out quite a few times to get a good fit.

A stainless steel lid is fabricated to keed the lead in place when the boat capsizes. Many screws are holding it in place. This is a test run.

The date was Friday 13. After work on the bike home I congratulated myself to having escaped all bad luck.

Next day I awoke with a broken back. Its now healed.

The small bollard in front of the cam-cleat I made for the yellow boat was a good idea. One turn of the sheet around the bollard reduces the force by 90 %. A secound advantage is that it act as a lead if the sheet comes in from a different angle.

In the case of the cam cleat being broken I can cleat the sheat to the bollards.

On the yellow boat.

The new one during construction.

From a different angle.

To be continued…

Regards Yrvind.

BALLAST

In principle, I am against ballast, but the boat has become to heavy, especially high up. At the start of the voyage from Ireland Exlex will be overloaded, halfway to New Zeeland, after five months of sailing, when south of South Africa, half the food will be gone. At the same time I will at 45 degrees south, meet heavy weather then with ballast and me having after 5 months adapted to the boat and life at sea and with the southern summer in November coming up I think same ballast, after all, is a good idea.

Below are some pictures showing Peter helping me to cast the lead pigs.

The melting pot.

Some of the lead being melted.

Peter putting the model in the sandbox.

Adding sand

Compacting the sand with a piece of wood.

The sandbox is turned upside down.

The model is remowed. Next step the top sandbox can be put on.

Peter is pouring the molten lead.

Peter is remowing the lead pig.

The lead pig is cooling in the cool snow.

I am cutting of the raisers with a wooden saw.

After grinding of the ruff surface i encapsulate the 6 lead pigs weighing 150 kilos in NM-epoxy. They are ready to be inserted in the boat.

The will not be glued in place becouse I like to have the option to remowe them for exemple beaching the boat or having her on a trailer behind a car,

To be continued…

Regards Yrvind.

Fairleads for the stearing lines

Happy New Year from Yrvind.

At present I am doing fairleads for the winch for the stearing lines.

There are two rudders. Each rudder have two stearing lines therefore four winches. Each winch needs two fairleads so eight fairleads.

I am making them out of Tufnol rods. Tufnol is wery wear resistant, so are some other materials. The advantage of Tufnol is that it unlike many fat plastics glues very well with epoxy.

Below the fairleads coming from the lathe.

I attatch them to a piece of 5 mm Tufnol board with polyester string and NM-epoxi. The polyester string also takes epoxy well.

I soak them in epoxy.

After trimming and drilling screw holes products are ready. Next they will be scruved and glued in place.

Becouse its a hobby I do better work than I have to. Of course in stormy weather you feel snug and fine and proud to.

To be continued…

Regards Yrvind.

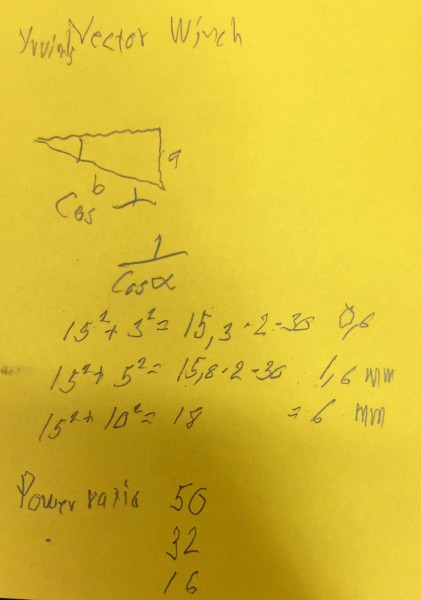

A WINCH TO ADJUST THE STEARING LINES

Not many people today sail without autopilot or windvane.

I do becouse its simple, cheap, takes up no space and is fun, also few things can go wrong.

A few things have to be kept in mind, no play in the system and a possibility to adjust the rudder angle rather precicesly.

On Bris I had a wheel and it was geared 10:1 to the rudder, that is ten turns of the wheel turned the rudder once. Adjustments of the spokes had to be done not more than a few millimeters at the time as the wind did change.

On Exlex there is no rudder. The stearing lines goes directly to the tillers. I realise i need a product to reduce line movement. The boat will move about in big waves. I have come up with the following device I call it a “Vector Winch”.

It works on the swig principle. The way you haul a line, especially a halyard, taut manually.

Theoretically it has a power range from infinity to minus 2.

For 30 cm between the fairleeds if you mowe the line 30 mm at right angle to the tension the line will be 0.6 millimeter shorter a reduction of 50 to 1.

50 mm shorten 1.6 millimeter reduction 32 to 1.

100 mm shortens line by 6 mm.

This way I can fine adjust my rudders.

Photos below show a mock up. It works wery well.

There is 30 cm between the fairleeds and two line jammers.

Me happy with my device.

Tension the winch:

Below Photo from the side:

To use the device, release the jammer close to the tiller, tension rope the desired amount, close the jammer, release the secound jammer, take up the slack, close the secound jammer. Done.

These products will be mounted abouve my bunk where i spend most of my time reading sleaping drawing on the next boat “Boat Ideal”. When I am in other parts of the boat the jammers are released that way I can steer from every other part of the boat also.

To be continued…

Regards Yrvind.