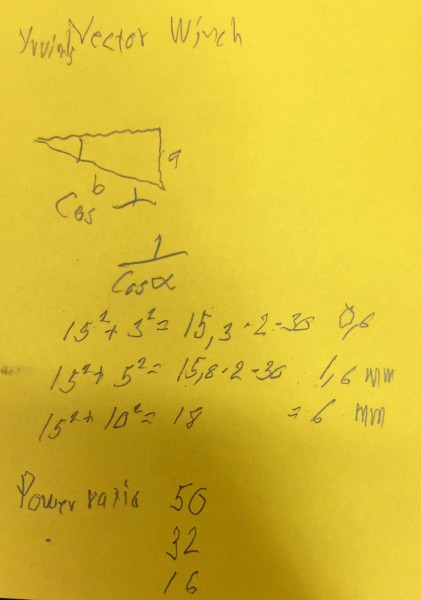

To invent a small cheap functional sextant capable of measuring any angel up to 90 degrees and accurate and rugged enough for life raft use my thinking went like this. I imaged a fixed angled Bris sextant, then one more to the left having a slightly smaller angle a third one to the left of that with an even smaller angle and so on down to zero. To the right I imaged a series of Bris sextant their fixed values kept increasing up to 90 degrees. After that I imagined the steps between them becoming smaller and smaller. After that still in my mind I glued them all together. Now I had a thought model of the finished product, one long sextant with twisted mirrors.

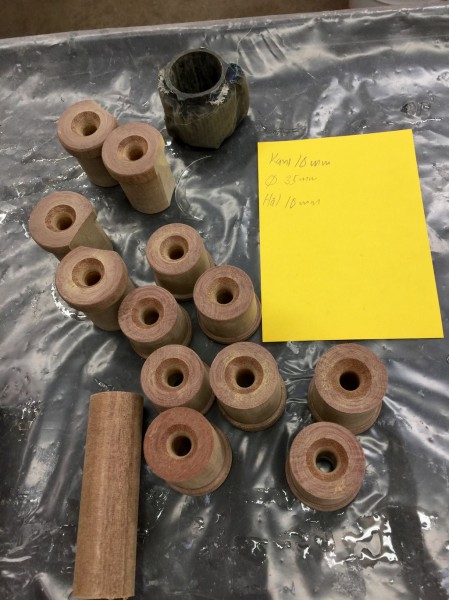

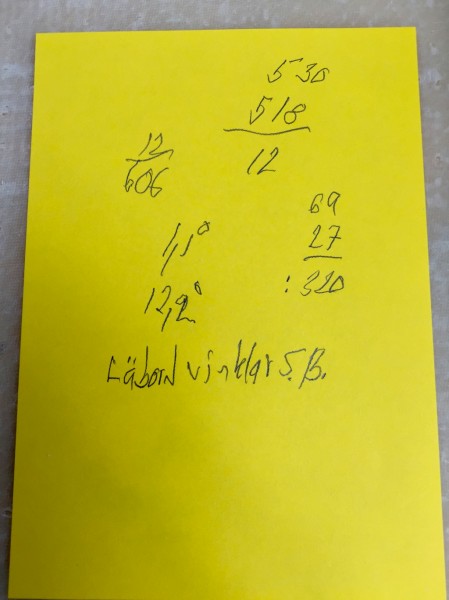

I made the first test by taking two strips of tinted semi reflecting acrylic glass and putting them together, one on top of the other. I joined them in one end, and then I twisted them at the other end to the desired angle and fastened them so together. I added a scale and a cursor to make reading easier because the human eye cannot focus so close. I have the option of adding shades to the cursor.

When taking a sight I hold the instrument close to my eye in a horizontal position, looking through it at the horizon. To move the image of the sun up and down I move my instrument sideways. When the sun is touching the horizon I note its sidewise position in relation to the scale and time it.

The next step is with the help of my position and the time to calculate the suns altitude. That way I find the corresponding altitude of my instrument at that point on the scale. I repeat the procedure for a few different angels.

As there are an infinite number of different angels there is no way I can calibrate them all, but that’s not necessary. It is enough to calibrate a few well spread out spots and make a table of them. To find any other angel I extrapolate or interpolate.

There is two ways to achieve the desired accuracy without a long and cumbersome instrument. One is to make a set of shorter ones, for example a set of three 30 cm long instruments with angels 0 – 30, 30 – 60 and 60 – 90, corresponds to a 90 cm long scale giving 1 centimeter for each latitude.

Eighteen instruments each 30 cm long will give a total length of scale of 5.4 meter long. Still the will require less space than a conventional sextant.

The other way is to make one instrument, like the Bris sextant with several mirrors that crate several images of the sun, spaced to the desired angels. It’s a neater solution but iterations or calculations will be needed to achieve the desired results.

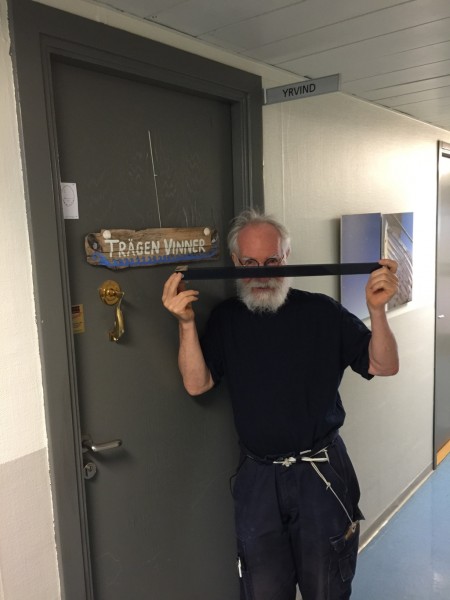

The Bris Sextant and Yrvinds Survival Sextant are both interesting products and they complement each other. The Bris Sextant is extremely small and exact, but like a set of sockets has only fixed values. Yrvinds Survival Sextant is not so exact but can measure all altitudes a bit like an adjustable spanner.

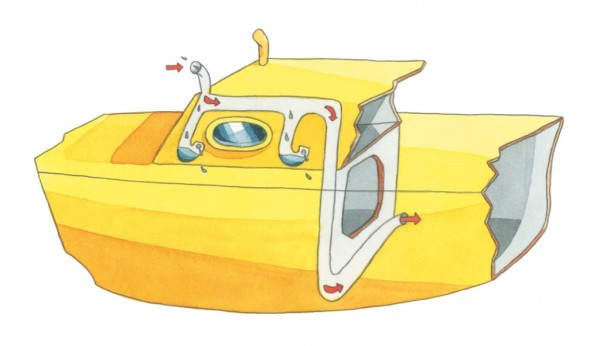

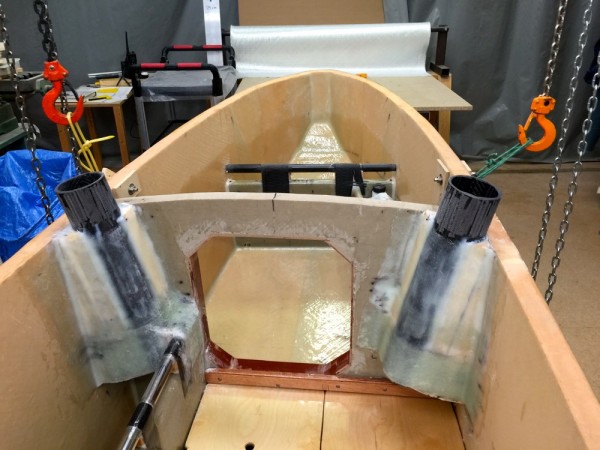

Me, I have leave these experiments for time being to focus on my boat Ex Lex. Boatbuilding is also a lot of fun as is sailing the finished product.

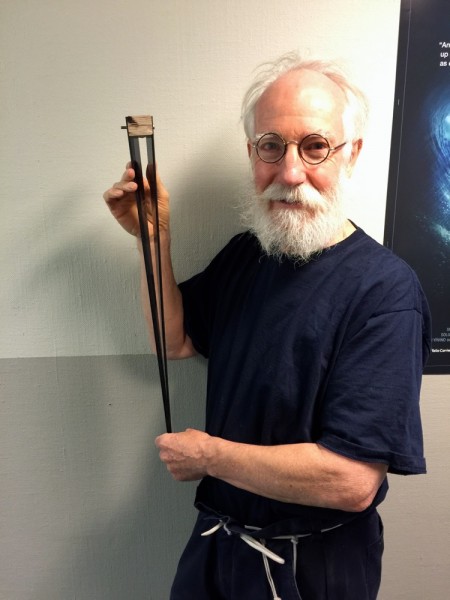

ABOUVE. Long version of Yrvinds survival sextant. To take a reading, slide the sextant sidevays, that will move the sun upp and or down. When the sun touches the horizon time it and note how far sidevise the sun is on the scale. No moving parts.

To be continued…

Regards Yrvind.

Like this:

Like Loading...