A QUESTION FROM FINLAND

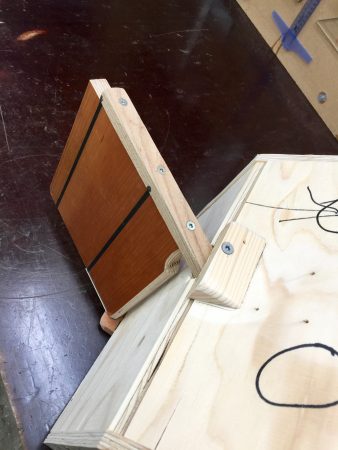

He ask if it is not better to have more dense material in rudder and centerboard as not to stability due to flotation.

Yrvind answer:

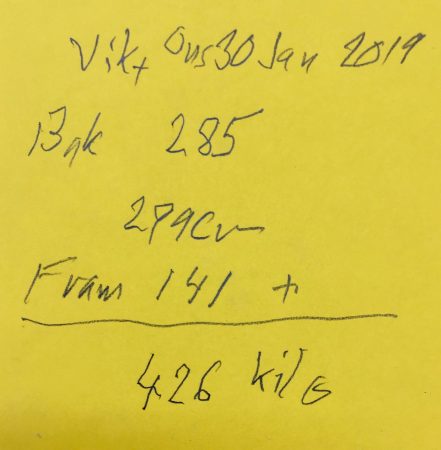

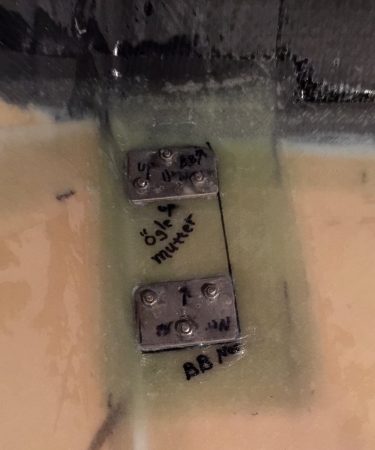

Heavier materials low down will give more stability. Added lead will give even more stability. In the case of the centerboard, when the board is raised, more weight will make the boat lose stability.

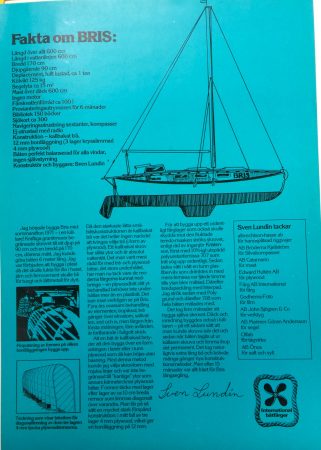

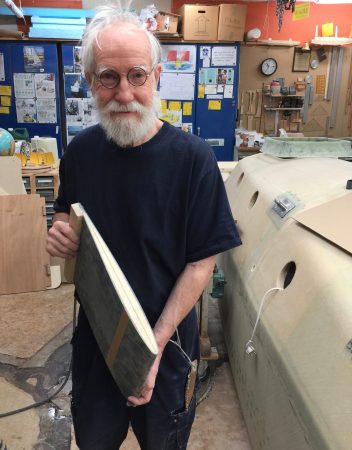

Almost every boat is designed as if it was to be a racing boat and the same with books about yacht design. Exlex is intended for cruising, when cruising I sail mostly down wind, even though I plan to round Cape Horn, 50° south to 50° south, east to west. Exlex is designed as a low energy boat and cruise at low Froude numbers around 0.3 this reduces the energy needed to about 1/6 of a conventional boat. See my Manifesto for a more detailed explanation.

More weight in the appendices will put more strain on them; they have to be designed more heavily. This added weight would make the boat slower down wind. It will also make the boat bigger and heavier and more expensive.

I think most boats are sub optimized for windward work. Neither do I think a cruising boat shall have weather helm.

Regards Yrvind

Like this:

Like Loading...