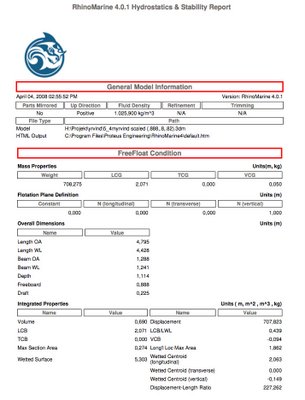

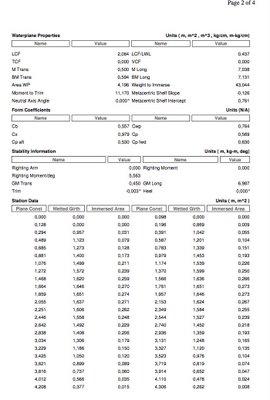

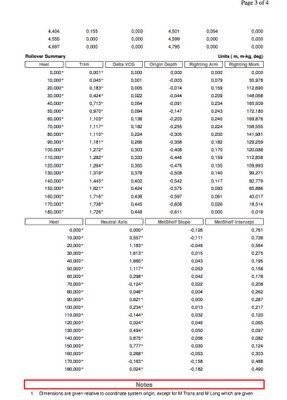

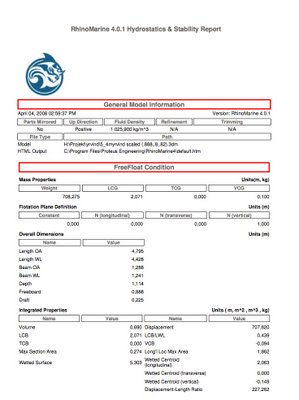

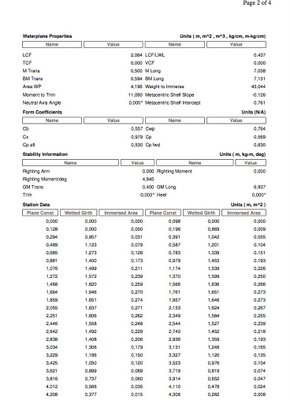

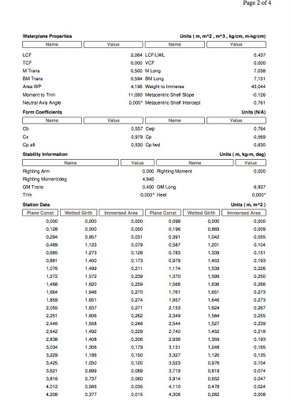

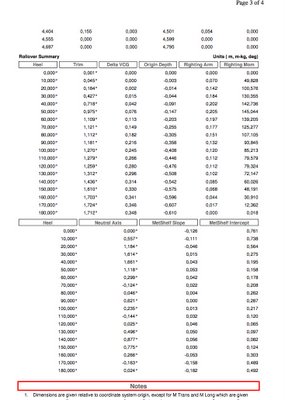

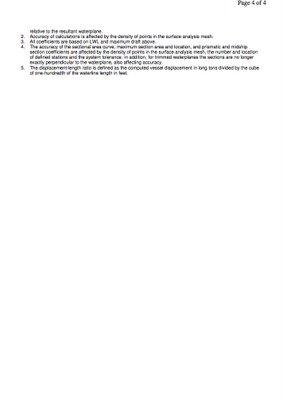

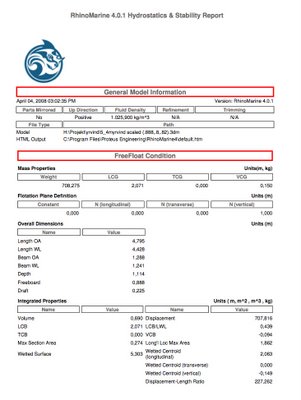

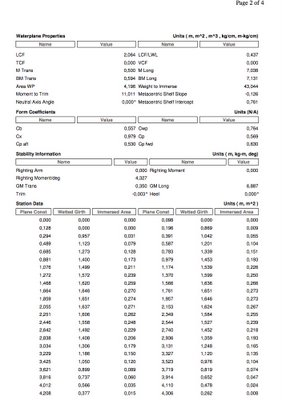

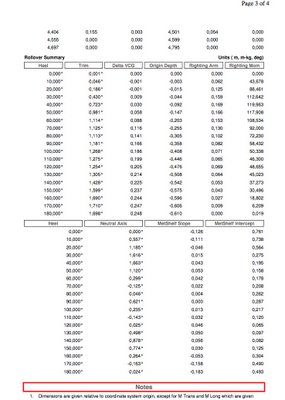

Here are some stability calculations and other numbers who Guy Lilljegren kindly has provided me with. There are three sets for center of gravity for 5, 10 and 15 centimeters above the waterline. Hopefully the center of gravity will come out at 10 centimeters above the waterline, but only the Gods know for shore. The numbers are really too small to reed but if you click on the pictures, first one time, them again, they get bigger and bigger.

QUANTUM SAILS KUNGÄLV SPONSOR MY SAILS

I have been very fortunate in that Quantum Sails Loft in Kungälv have undertaken to sponsor me with sails. From previous experience I know that the do an excellent job. Below is Patric sewing on a sail to Yrvindaren. (see photos)

Here Henrik is showing all 0.5 sq meter of it.

Quantum sails will sponsor an illustrated lecture in Göteborg on next Wednesday the 29 October 6 30 pm. If you are interested in hearing me talk about my voyages take contact with quantum sails phone 0303 10818 The talk will be in Swedish.

THE LOWER AFT DECK IS NOW DONE

STARTING ON THE LOWER AFT DECK

The last work on the interior is now done, it was getting some NM-epoxy on the underside of the shelves. To make the epoxy flow in the right direction I turned the boat upside down and on its sides.

I also weighed her. She was at 250 kilos or 550 pounds found lean and strong.

After that I started on the lower aft deck. Here I am fitting the frames to the deck curvature which is 85 millimeter high on 1320 mm beam.

Here looking aft, having removed the pattern.

The frames are ready to take the Divinycell which for the deck and deck house I use a thickness of 30 mm and a density of 80 kilo per cubic meter.

After laminating the inside with one layer of 600 gram quadruple glass in NM-epoxy I bend with the help of lead weights the panel over the frames.

To be continued…

RUDDER & BOWBOARD

Kåre Ljung an areodynamiker one of Ridders disciples, now working at Marströms, has helped me to modify a NACA-profile to suit my demands.

Here Gösta Larsson who kindly has offered to help me mill the rudder and CB Divinycell-core is programming his NC-machine to do the job.

Here Gösta is adjusting the machine.

Here he is advising me how to watch the machine mill the divinycell to size. The tolerance of the machine is better than a hundred of a millimeter. Fare more precise than what I need.

Here Im watching the machine doing the precision work. Thank you Gösta and your company Larsons mekaniska i Hjorted.

In the meantime Börje from BT-Hantverk has done the rudderfitting. Shown below.

Here I am doing a bit of mockup with the stearing lines I use instead of a tiller, saving a bit of place on my small aft deck. Tacking care that I get a god angle of the lines also when the boat is going backwords and there is a reverse pressure on the rudder.

Sad comment. Even in our little quite town of Västervik there is vandals, bored people. Here someone has destroyed our nice little clock in the park outside by throwing a stone at it.

One of the good things with siglehanded ocean sailing is that you are fare away from the vandals. Life on the ocean wave is freindly.

THE MATTRESS

Thanks to Gunnar Bäckstrand of HGB BACKSTRAND AB I now have an excellent mattress which will protect me from the cold Cape Horn waters. It is 6 cm thick made of closed cells which means that it cannot get wet. Whith 6 cm mattress and 4 cm divinycell foam in the hull I will have a total of 10 cm or 4 inches insulation. If I then also can get hold of some old blankets in Argentina I will be worm and snug in my boat.

The picture below shows me cutting the mattress material to size.

The picture below shows the mattress in the bunk. The size of my bunk is length 191 cm, wide at feet 40 cm, wide at head 68 cm. It is a bunk impossible to fall out of. Very secure.

MORE ABOUT THE LEAD WEIGHTS

Now all the lead weights are cowered with kevlar for wear resistance and to prevent myself by being killed by lead poisoning. The front end have gotten a teflon patch to slide more easily into the lead chambers. The stainless steel handles are in the back.Without them it would be very difficult to handle the weights in heavy weather.

Below is a picture with all the weights secured in the extreme aft position. Their intended position when im running down wind in heavy seas, to give the boat directional stability and to increase her mass moment of inertia to help prevent pitchpooling.

AT THE FOUNDRY

I did not consider my self competent to do high quality lead castings with no porosity or hollows. After much searching I found Bo in the village of Blomstermåla (its name means “the painted flower”) Here Bo is outside his foundry.

After having put the model in sand the inlet and a substantial raiser is added.

More sand is poured

The sand is compacted.

The lead is poured.

Here is my weight with inlet and raiser which are sawn off with a bandsaw.

The pieces with its stainless steel handle weigh 14 kilos or a bit more than 30 pounds each. In the boat there is place for six making 84 kilos, the weight of a big man. I always make a few extra. I have six spare ones to select the best and in case I make a mistake. Below is some of them.

Below the final product swept in kevlar for wear and with its handle.

Thank Bo and the personal at Blomstermåla foundry for a well done job.

CAPE HORN, THE NEW CHALLANGE

My plan was to sail Yrvind ½ to Australia, but after working with her for more than six months, finding ways to make her more weatherly and seaworthy I now think she is capable of more. I now like to try an east to west Cape Horn rounding in her.

I dont think that it will be easy, but I think if life is not difficult its not worth living. If you work to the limits of your capacity you do not get bored and you do not need entertainment and drugs.

The east to west rounding is called the wrong way. It is nothing wrong about it. Cape Horn earned its reputation by forcing Captain Bligh to give up, by giving the 1849ers who sailed to California looking for gold a harsh time. Going east about helped by wind and current is not the same achievement, nor is it to hide behind the nearby islands or in the Beagle Channel until you have a god weather report and then make a quick dash around.

The sailing lores old and well established starting point is latitude 50 south in the Atlantic, its finishing point is latitude 50 south in the pacific. It is an east to west rounding.

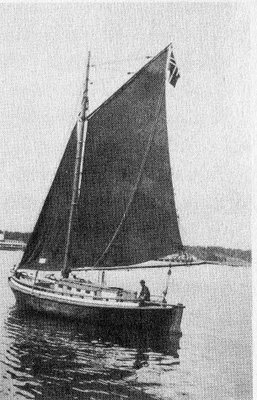

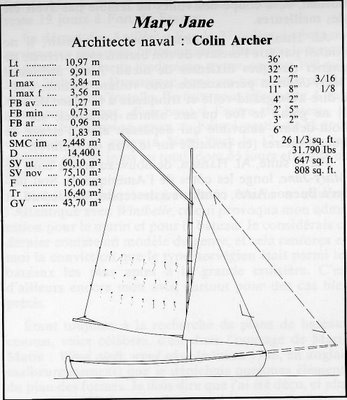

Singlehanded in a small boat that challenge is difficult. In fact to my knowledge only one person has succeeded doing that in a boat smaller than 60 feet. That person is Alfon Hansen from Norway. He sailed in Mary Jane a 36 feet gaff rigged Colin Archer. He had no engine. He left Buenos Aires in 1934. He arrived in Isla Chiloe 110 days later. After a brief rest he sailed north. He disappeared at sea in a storm. Only wreckage of Mary Jane was found.

Some people may think it is hubris to try to round the Horn in a much smaller boat, but i do not want to be remembered as a down wind sailor.

Below is my planned route, from Mar del Plata in Argentina to Valdivia in Chile.

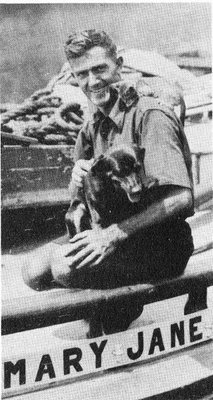

Below is a photo of Al Hansen with his cat and dog.

Below if a a photo of Mary Jane.

Below is particulars of Mary Jane.

MORE WORK ON LOCKERS

The vertical subdivisions behind the side panels are now done.There are four on each side in the fore cabin and the same amount in the aft cabin. I have now also begun work on the shelves. There are nine lockers on each side in the fore cabin and six on each side in the aft cabin, a total of thirty. There are more than three hundred liters of stowage for books and food. There are also eight water jugs under the aft deck, five liters each, four on each side. They are connected to my water catchment system. A small slow boat on a long voyage needs a lot of secure stowage.

Below is a picture of the fore cabin. At the bottom of the picture on the starboard side can be seen the shelves, the horizontal division of the storage space, coming up.

Below is one of the shelves. The clamps hold iron angels which the shelves rest on. the lead piece holds the shelf in place while the fillets cure.

Before this was done I had made the lead chambers here is the six ones on the starboard side. There is a total of eighteen. At this moment the lead weights is being poured at Blomstermåla foundry. More about that later. Each weight is 14 kilos or about 31 pounds