MAKING YRVIND TEN STEER HERSELF

Modern ocean going yachts have electric autopilots. There are still a lot of wind vanes around. A simpler way to steer a yacht is by the “sheet to tiller method”. Slocum balanced his Spray. I have made many ocean passages in different boats by balancing them. It is not the easiest way but it is the simplest. With a locked rudder and preventers to the sails nothing moves and everything is quit except the gurgling of the waves along the hull. It is not the fastest way but it is serene.

Any a sailboat with her centers in their right place will steer herself upwind. If she falls off her set course more wind will hit her sails and she will heal over and the center off effort will move to lee and give her more windward turning leverage. As she comes back towards her set course she will heal less and the rudder will make her fall off. This pendulum oscillating movement will to the naked eye keep her on a straight course much in the same way as a pendulum clock gives us time at steady rate.

It is negative feedback.

Downwind is a different matter. There the sails gives positive feedback, the more the boat wanders off course the worse it gets.

A few things make live easier downwind, a short rig, little healing, center of lateral area far back and very important the ability to adjust the rudder precisely. It is often a question of fraction of degrees and it has to be re-adjusted for changes in wind strength.

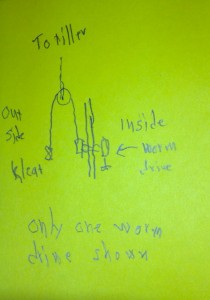

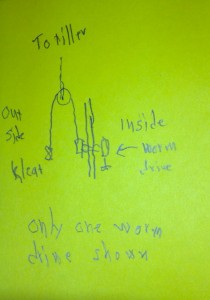

To make things easy for myself on this long stormy voyage I am planning rudder control from inside and outside. An axis is passing through the side of the deckhouse. Its inside end is connected to a self-locking worm drive. The outside part of the axis has a reel to take a rope; the rope passes through a block on to a cleat. Holding the block is another rope that connects to the tiller.

Working from the outside adjusting the tiller is done from the cleat side, from the inside by the worm drive.

As there is two rudders and each rudder needs two lines to control it I end up with four worm drives. First try was with trailer winches, kindly supplied by Watski, but they were to heavy 4.5 kilos each. Next try was with awning worm drives. They only weighted 0.55 kilos each. Like products designed by Steve Jobs one was not supposed to take them apart, but with some force I succeeded. I like to know what I ship.

With this set up I can independently from inside or outside precisely control the rudders. As I have written before by wedging the rudders I can slow the boat running before gales.

Below are some pictures to illustrate. First the winch worm drive.

secound picture awning worm gear opened with force. It passed inspection.

Third picture is an sketch diagram whose purpose is to try to clarify the above. If you do not understand more will follow.

The boat is now in a garden in the island of Wärmdö near Stockholm. Wendsday I hope to take her to the boat show.

The Göteborg boat show was an succes but the exhibitor caught a cold. I have convalesed. Henceforth to preserve my health at boat shows I will decline offered handshakes.

I am eager to be back to working on the boat.

Regards Yrvind.

Like this:

Like Loading...