Cecilia was a nice beutifull smart girl I met in Brazil 1979 when I was there in Alu-Bris on my way to Cape Horn. She was only seven years old then, but now we have found each other again. She has made five little films for me. This is the first one. Se more films from Kvarteret Filmproduktion.

EXTENSION LAMINATED PART 2

Today I removed the pealplay and turned the boat over to evaluate the new set of possibilities and do some work on the inside. Meauring the boat she turned out be 5.76 meters, 18 feet and 11 inches, pretty close to 19 feet a bit longer than expected. I am pleased.

Foto 1 me with the ripped of peelply.

Photo 2, Me at the end of Ex Lex.

The extension will contain a box for more food, swim fins, snorkel and diving mask and such things. Behind the box a swim plat form that includes ground gear. Mock ups will determine it.

Also there will be a boarding ladder which foulded up and extended behind the boat will support the yuloh. Raised even more it will be an safe and comfortable place to excrete from.

Ex Lex will have twin rudders.

To be continued…

Regards Yrvind.

EXTENSION LAMINATED

Today Petter helped me to laminate the extension.

It went well.

Below are 3 photos.

Petter and me.

One more from an other angle.

Me and Ex Lex.

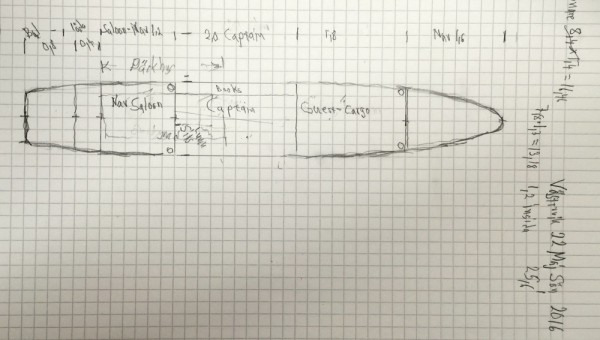

The boat is getting closer and closer to my “Boat Ideal” which is today 7.8 meter long by 1.3 meter beam. Ex Lex is 5.65 long by 1 meter beam.

Yacht design is an iterant process “Boat Ideal” will have the same square section. I wonder if she will go to windward without leebord or other lewaypreventing devices.

Might not the flat sides function a bit like a chinerunner now that she has a lenght/beam ration of six?

When healed over say 20 degrees she presents a lot of flat surface to lee, several square meters, many times more than other boats keels or centerboards. After all a hulls weatherliness is the ratio of her resistance to lee compared to her resistance forward. A long slender hull with flat sides has much to speak for her although a fin keel is more efficient per unit of surface the slender hull more surfaces and uses them in other ways to, like to get a very low displacement lenght ratio, say below 150 and for a given displacement a longe waterline lenght.

She will most probably not be as weatherly as a finkeelboat, but well satisfay my desires as well as give a uncomplicated shallow draft cruiser.

Also for my use, in the narrow boat I can make a much better layout.

Klick once or twice to enlarge.

I think Ex Lex will give me a good indication of how “Boat Ideal” will work.

To be continued…

Regards Yrvind.

STILL MORE WORK

Here are some more pictures of stretching the boat.

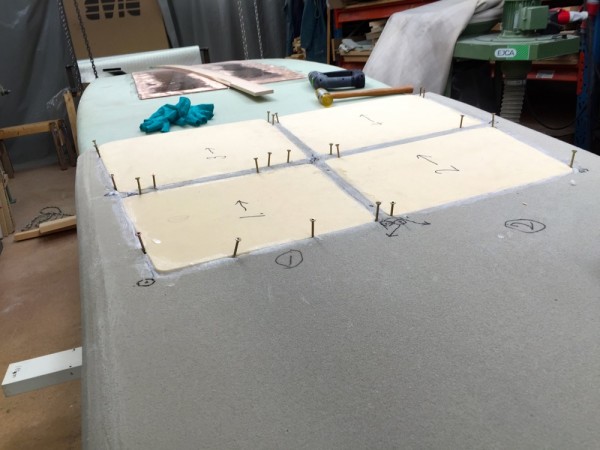

Making lids for the cut holes.

Fitting them into the holes.

Gluing on a smoth transition with Divinycell of diminishing thickness.

After a bit of gringding.

Turning the Ex Lex 90 degrees to do one of the sides. To avoid damaging the Divinycell glued on and to get the lifting point abouve the center of gravity I am using a beam. Picture 1.

Picture 2.

Picture 3.

There is plenty of space in the added section.

To be continued…

Regards Yrvind.

MORE WORK

When I stretched Ex Lex I got double planking and bottom for about 60 cm. The solution is to remove the extra inner bottom. Se pictures. Unfortunately I can only do that from the outside, but I will gain about 30 liters of stowage space and that will be worth it because those 30 liters of food might keep me alive for 2 or 3 weeks. In total I estimate that the stretching will add 250 or so liters of stowage.

As I said before Ex Lex started out as an experimental boat with two purposes, to teach me about the new rigging, leeboards and others things, also to give me a bit of fun I the summers.

Few plans survive first contact with reality. When I saw Yrvind Ten and Ex Lex next to each other I realized how ridiculous Yrvind Ten and the project was. I used my good recipro saw and a carbide tipped blade. The boat was well built, but after a busy weekend, two friends helped me to drive the pieces to the dump.

Ex Lex the new boat will have fewer problems crossing the Atlantic equator southbound due to her much longer waterline. Few if any small boats have done that crossing.

That passage is special because you meet the south east trades head on at the same time as the equatorial current carries you westwards with a speed of about one knot or 24 miles a day and than if you have not made enough southing before you hit the longitude of eastern Brazil you will be carried back up to the North Atlantic and will have to do as the square riggers of old days had to do, make a circuit of the North Atlantic before you can try again.

The southeast trade has a fetch of several thousands of miles and blows freshly. The waves you are heading into are impressive.

I have done that passage three times. Analyzing the forces acting on my boats I have come to the following finding.

I knew, and it is well known fact that a small floating artifact in big waves is subjected to a centrifugal force that is considerable. On top of the wave you are lifted, in the trough you are depressed. On top of the wave the centrifugal force is subtracted from gravity. There it’s like being on the moon, you weigh less. In the trough gravity and the centrifugal forces are added. There it’s like being on Jupiter, you weigh more.

A displacement boat can only travel as fast as its wave system and when that wave system is on top of the wave it weighs less, therefore it and the boat travels slower. The speed of a wave system depends on the forces acting on it. The speed is high if forces are high and slow if forces are small. On top of a wave where there are small forces. Therefore, there a displacement boat cannot travel as fast as on flat water or in the trough its being slowed down.

Another consequence of the boats little weight on top of a wave is that she is losing stability. She heals over, losing driving force and lateral resistance. People think this extra healing at the top of a wave is due to more wind. The fact is, its normal to lose more than half the stability due to the influence of the centrifugal force. Stability is a function of weight and weight is lost at the top of the wave.

Another complication is the surface current that on top of the wave is travelling with the wind against you. This means that three bad things oppose a small boat going to windward in big waves when trying to cross Atlantic equator from north to south.

The boats sail force is not big enough to overcome this momentarily increased resistance; therefore the boat has to borrow a lot of kinetic energy. That slows her down.

Now with Ex Lex much longer waterline I am more confident of making it across the equator. If I had tried sailing with the late Yrvind Ten my best chances would have been to hug the African coast, but there, there are pirates. Down in the Southern Ocean it’s a question of surviving storms and spending time and that is a different set of problems that I do not worry so much about.

Some pictures:

Above looking nice.

Holes are cut.

A lot of cutting, grinding and unpleasent work.

Starting the rebuild.

To be continued…

Regards Yrvind.

THE MAST SUPPORT

Ex Lex masts are free standing, still they need support. The boat will have 2 or 3 mast there will be a holder in each corner of the boat in the form of a carbon fibre pipe.

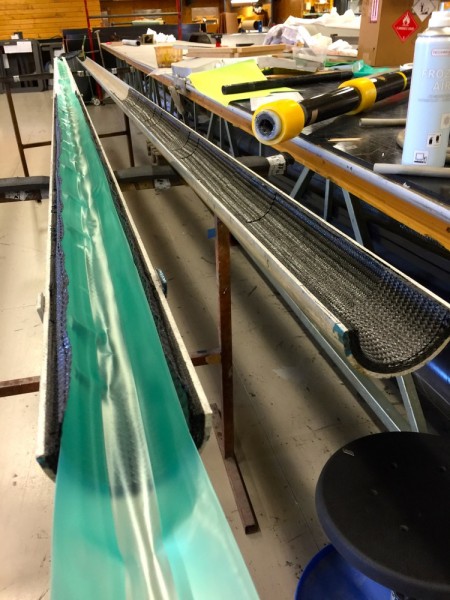

Below are some pictures of how I made the tubes a two meter lenght cut down into 4 pieces each 50 cm long.

The masts are Europe Class Dingy masts cut down to size. The original sleveve where made of POM or acetal or Delrin. To me that did not have enough wear resistance.

Kindly UV-elast of Mariestad made a 1 meter long piece for me that I cut down in pieces.

After I put down the phone the man went right down to the factory and poured it. The next day I had it in my hand.

At Marström Composite 500 meter from my home here in Västervik at the Swedish east coast I am starting to build the pipe using prepreg carbon fibre.

Testing to see if the mast and the polyurethan sleeves fits in the pipe.

Putting in the inside vacuum bag.

The outside bag is on and the vacuum applied. The black butyl tejp closing the bag can be seen. There can be no leaks.

The product in the autoklav. When the door is closed 4 bar pressure is put outside the vacuumbag and the air is heated to 120 degrees celsius. After 3 houers the product is done.

Below the mast in the pipe.

There is play that it will not stick. I will put up and take down the masts as other people do their reefing.

To be continued…

Yrvind congratulates Manie to his progress. Nice choice of colour me thinks.

Yrvind thanks Angelique for the artickle on dyslexia. A French publisher is interested in my book. We are looking for a translater Swedish to French. Pierre Herve have done plenty of excellent illusstrations. God willing we might see a book one day.

Regards Yrvind

THE MATTER OF FOOD FOR A SMALL BOAT ON A LONG VOYAGE HAS TO BE TAKEN SERIOUSLY

Beside sardines I will eat energy bars. Below is a photo of my fiend Petter helping me to find a good formula.

On a long voyage the fat in nuts powder milk and such can go rancid, to prevent that I have acquired a chamber vacuum packing machine. Möllerström have supplied the machine, AGA and Pylad have supplied inert gas.

Below me, the machine and the gas tube among my books in my one room flat.

The vac creates 99,8 % vacuum. That way the fats cannot oxidize and get rancid, but the package also gets hard as bone. That makes a tight stowage impossible because there will be spaces between the parcels. To get around that I fill the empty chamber with 30 % inert gas a mixture of nitrogen and carbon dioxide.

That way the parcels get soft enough that I can mold them into such a shape that they fill out the available space in a desirable way. The gas in the parcels is inert no oxidation can happen and there is enough outside pressure on them to make them compact.

Bonus: Below a picture of me and Robban at a TV show Stockholm yesterday.

To be continued…

Regards Yrvind.

I HAVE TWO HOBBY’S

Me looking out of the mock up, dreaming of the big oceans.

I have two hobbies, amateur boatbuilding and small boat sailing. The root of the word amateur is amour. An amateur boat builder builds with love. For me it’s an immense pleasure to solve problems and hopefully come up with something good.

Every morning I go to work filled with joy. Every evening I proudly look at what I have accomplished during the day and feel great satisfaction.

A good amateur boat builder builds a much better boat than a professional. Not necessarily because he is so much more skilled or more clever, but because the professional boat builder is restricted by economics and time pressure. The professional boat builder is forced to use as cheep and inferior materials as he can get away with. He cannot spend more time on a product than is economical defensible.

Professional boat builders go to work to earn a living, not because they enjoy their trade. Many of them, understandable, do not look at their days work with pride.

For me, my days, weeks and months pas quick; still I dream of the day when my boat will carry me across oceans. For more than fifty years I have been building boats for my voyages. I have made many mistakes and not all of my boats have been successfully. Yrvind Ten, I did build with money, not love in mind, although it was an interesting engineering project my heart was never in it. With Ex Lex it’s different, therefore I feel good about her.

Most people, including journalist, find sailing more exciting to watch and write about than boatbuilding, they keep asking for the launching date. That is unfortunately, because on a well planned and well executed voyage not much exiting things happens. On the other hand watching an innovative experimental boat take shape, that is exciting because a lot of surprising things do happen.

Of course, to go into details and start building from the fundamental principles takes more time than to walk to the ship chandler and buy the item off the shelf. Not just a little more but much more time. With a standard part the job might be done in half a day, by going back to the fundamental principles it usually takes weeks.

Friend of order will say, this is a waist of time, but friend of order misunderstands life. Life is not about producing a lot of things fast. If building slowly gives me pleasure and harmony, friend of order should not try giving me bad conscience. On the contrary, I think the world would be a better place if people did not make so much haste.

Out in a storm, I never regret time spent on a job well done. On the contrary knowing that I have made my best makes me feel wonderful when I am far out on the waste, lonely ocean, when I am in the grip of furious, ruthless storm, because then I know that nothing whatsoever can happen to my little boat. The big waves can shake me tired, but they cannot make me scared.

This is in sharp contrast to people sailing production boats built by professionals how did not care.

To legally sell a boat in the EU it has to confirm to The Recreational Craft Directive which sets minimum requirements of a boats safety to guarantee its suitability for ocean passages, class A. This sounds reassuring at first, but the surprising fact is that that guarantee does not include weather above force 8. To my mind an ocean crossing boat must be able to survive storms, not just gales.

The Recreational Craft Directive makes it illegal to sell small boats for ocean passages, only big boats are safe according to the directive.

Of course big boats are not safe. Big boats are dangerous; they create large forces. To control them complicated technology is needed. The more complicated the technology is the more vulnerable it is, especially in marine environment.

Of course I worry when building my small experimental craft, will she be to heavy, will she have enough stability. Will my money be enough to finish the project?

Still I do not have bad conscience because I do not hurry my work. Persons visiting my webpage shall know that everything is fine that I enjoy my work and that I am happy. I like to make sure that people understand because I am happy now that does not imply that I have given up my plans for the ocean, indeed, it’s the desire to sail the ocean that is the driving force behind the building of Ex Lex.

The joy of cooking does not exclude the joy of eating.

The joy of boatbuilding does not exclude the joy of sailing.

Do not hold your breath, there is still a lot of time before Ex Lex will hit the water.

Regards Yrvind

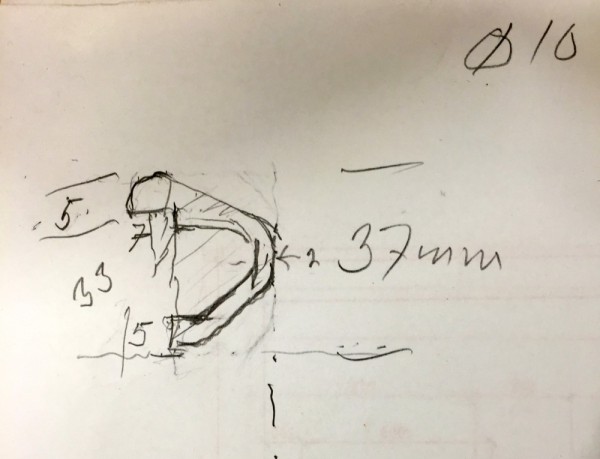

THE MAST HEAD FITTING

The lug sail is not attached to the mast by a track, only by the halyard. The pull varies at least 270 degrees. To utilised all of the mast the Ex Lex halyard comes out at the top of the mast at the center.

The diameter of the Dynema halyard is 6 mm the hole is 10 mm diameter.

Previus experience with POM aka acetal and Delrin has shown that it does not hold up to extensive wear. I therefore chose bronse even though it heavier.

Below are some pictures.

The first sketch.

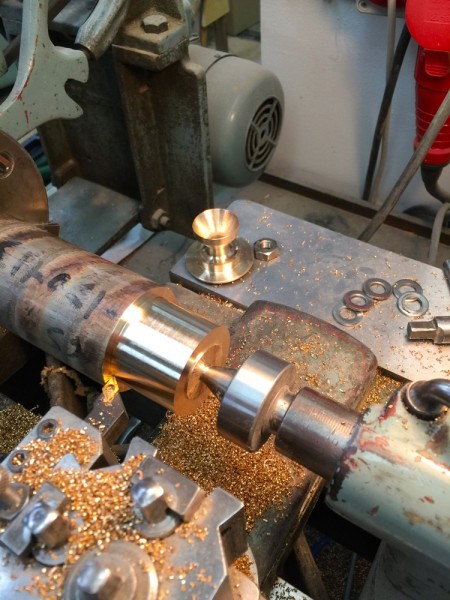

In the lathe.

Ready to be cut.

The finished product. Its conical on the outside as well to save a bit of weight at the top of the mast.

Ready to be tested with the halyard. The mast is the bottom part of Eurupe Dingy masts, donated by Marström.

I do not have inside halyard. A small piece of bent titanieum reduces wear on the carbonfibre.

Silicon rubber is inserted to create a epoxy tunnel.

The mast are standing upside down. Me injecting epoxy above the fitting, embedding it.

Close up.

After the the NM-epoxy has set the silicon rubber is pulled out and leaves a nice tunnel for the halyard.

This way of raising the sail takes more force than using a system with a pulley, because of friction, but the sails and spares are so small that its OK.

On the other hand its creates less compression on the mast (becouse of friction) and it has no moving parts and is omnidirectional so not much should go wrong.

To be continued…

Regards Yrvind.

A 15 MIN VIDEO

Here is a 15 min video showing Ex Lex. It will be boring for people that do not speak swedish. It does however show the boat and me crawling around in it.

It was shown at the Göteborg Boat Show Friday 12 2016.

This is the kind of weather the boathave to deal with in the Indian Ocean, south of Africa and Australia. The storms in the Roaring Forties is very evident.

Regards Yrvind