It’s safer at sea. On land there are many dangers lurking. To save my soul we’re training escaping from a fire that migth erupt at any time.

BATTERIES

A big moment. The 4 batteries are now here. They each weigh 19 kilos but are placed low down to add to stability.

Its four Sonnenschein GF 12 50 VG. 55 Ah at 20 degree temperature. They are gel batteries and can be dischareged to 80% 500 times. The idea is to have enough battery capacity to use a word processor and AIS for long times.

They are well secured. How wants batteries flying around.

Pictures below.

To be continued…

Regards Yrvind.

A DETAIL

Ex Lex is an experimental boat. On her I will test ideas for my next boat. Therefore I pay more attention to details than I would otherwise do. Here is an example.

There is 11 compartments below my bed for stovage.

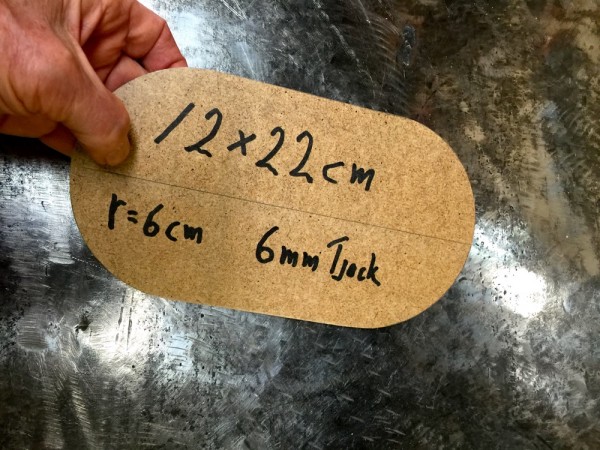

I will screw down the hatches covering them to be shure that things do not start flying around in strong winds. The hatches will be made of 12 mm birch plywood. On top will be an 3 cm thick mattras for me to rest on. I need an washer to distribute the force of the screw so that it does not eat into the plywood after repeated use. Also I do not want to many loose parts.

After trying a cupper pipe rivet I decided that it was not satisfying.

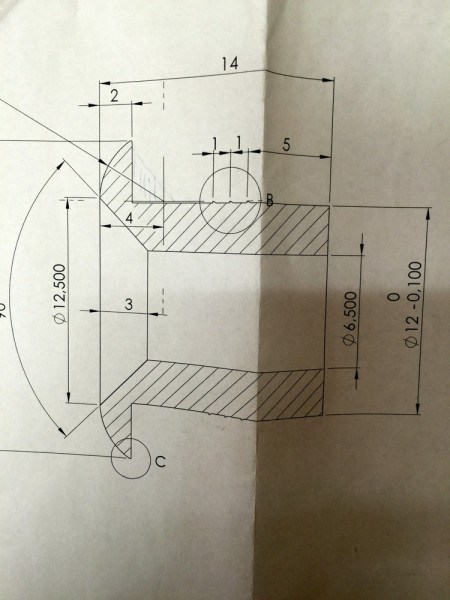

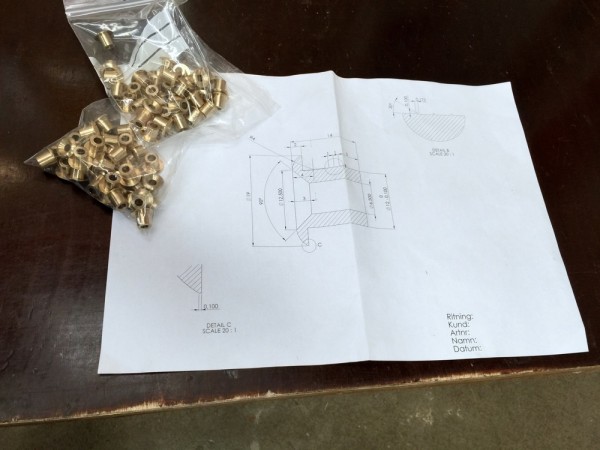

Tjust Mekaniska turned out the ones I wanted in bronze on their lathe.

The drawing

The products on the drawing

Testing on washer on a scrap piece of plywood. There are small ridges on the washers, also they be set in epoxy after first washing them in aceton. That way they stay in place.

This gives a satisfying feeling.

To be continued…

Regards Yrvind.

UPGRADING EX LEX

It started when I realized that I was doing wishful thinking. I was doing the calculation for how many calories I needed, based on a 78 year old man weighing 70 kilos, with sedentary activity, and little or no exercise. Then I converted the calories to kilos assuming 350 calories per 100 gram on the average for my type of food. I was quite pleased to find that I needed about 0.5 kilos a day or 135 kilos for 270 days. Reality is of course that on my small boat volume is the limiting factor because the food has a density of about 0.4 so 135 kilos becomes nearly 350 liters far more than my available storage space.

Of course I could divide the passage into shorter parts, but once I had the longer passage in mind, a shorter one did not appeal.

After considering several options I decided to raise the freeboards by 5 cm and build a storage space under the bed 20 cm high. That would decrease the standing headroom by 15 cm. A mock up showed that I could live with that. The space under the bed became 250 liters. That together with already existing stowage gave me plenty of room for everything.

To use the space efficiently I did remove the attachment pipe for the safety belt. That took some doing.

For the third time I moved the big anchor, padding the space with Kevlar for wear. I also moved the four 19 kilos gel batteries. There are now 11 compartments under the bed.

An other big change is to add a mast, making it 3 in total. The third mast, a short one, will be placed at the transom when in use or flat on deck when not needed. Its to give the boat weather helm and as a spare.

This allows me to move the leeboards further back where they are more parallel with the hull. Also I now can move the forward mast positions nearer the bow. That way they are easier to reach from the hatch.

Below are some pictures for illustrations, click on them once or twice for enlargement.

The bed before the change. The attatchment pipe in place.

The removed pipes. I had to use ealbow grease and force.

The storage space. The anchor and the batteries are well sexcured. There are two batteries in the picture. They are dummies, no weight at all. There be a total of four Exide, Sonnenschein 55 Ah

The modell with the big mast in the aft position. Giving the boat good weather helm in light wind. Having reread Knox-Johnston, Moistessier, Alec Rose, Duma, Alain Kalitka, Yves Gelinas and others confirming my own experince that there is plenty of east winds in the west wind belt 40 degrees souht. The three mast can be mowed around at will. The long one is 2.7 meter, the short one 1.8 meter.

To be continued…

Regards Yrvind

To my friends at boatdesign.net

http://www.boatdesign.net/forums/all-things-boats-and-boating/yrvind-39341-35.html

Angélique is right. 1947 they opend my stomach and removed an appendix becouse I told the grown ups that I got stomach pain when I had to go to school. It is unlikely that there is an other one left, so the chanches that I turn up at Houtbay to say hello to Manie in his ten feet boat becouse an appendix are small. Besides I do not think, appendix or not, that I will make it in time.

It worries me that Manie will make his trials in a bay, even though it might be a windy one. To test a boat for an ocean passage one should, in my mind be far out to sea so that one can spend days riding out a gales far from shore.

If I may suggest something it would be to sail the south east trade wind up towards St Helena. Often nice weather and one gets to know the boat, then south towards Tristan da Cuhna group and back to South Africa where stronger winds may be encountered.

Repeat that a few times. Of course first make sure in Houtbay, that all system work.

Of course it is easy for me sitting here safely in my armchair to give advise, but it is what I would consider if I was testing an offshore boat in those waters.

Regards Yrvind.

ABOUT GERMS AND CONTAMINATION

Some folks worry that I may infect the water in my containers by blowing into them.

My father and grandfather sailed the square riggers. I remember my grand father telling me that they got fresh water by taking one of their boats up a stream and filling it with water. That water contained quite a bit of organic matter. Nowadays civilized countries like Ireland from where I intend to start have water treatment plants that remove organic matter from the water and may even add chlorine. Germs need organic matter to grow. Pure water is only H2O.

After a month or so at sea I will start to collect rainwater. I do not think that rainwater will contain enough organic matter to give my germs anything to grow on.

Also my grandfather said that if the water was contaminated you should wait until it had rotten three times, then it would be fit to drink again. I do not know if modern science agrees.

If however, against all odds, my water should get infected, it can only be infected by my own germs and they will obviously not do me any harm.

I am now back from the Göteborg Book Fair. Hopefully I have sold my manuscript. It will take a few months before the publisher have decided.

I have also bought charts over the approaches to Cape Verde Islands, Uruguay, Good Hope, Tasmania and Southern New Zealand in case I get appendicitis or similar. I hope to stay at sea.

I have been to dentist to check my teeth.

I have been to the MN factory in Ytterby getting more epoxy glassfibre and fillers.

I have been to the Exide battery company in Kungälv to talk about battery’s and everything has gone well so I mow ready to do more pleasant work.

Regards Yrvind.

THE PROBLEM WITH NICE WEATHER

When Moitessier December 1968 to February 1969 crossed the South Pacific he had excellent weather. He relied on rain to get water, but he got very little rain so he started to worry. In the end he was alright.

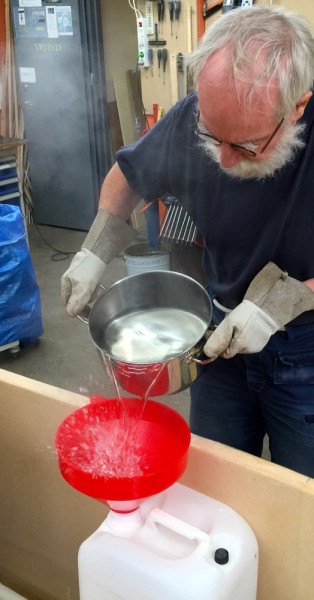

Moitessiers experience is on reason I have decided to increase my water storing capacity. I had 51 liters. Now I decided to add two 24 liter plastic jerrycans getting it up to nearly 100 liters. Unfortunatly my containers vere to big for their intended stovage. See photo below.

However polyethylene gets soft when warm so I poured boiling water in them. See photo below.

That did the trick. Nice and smouthly by force of gravity they sunk to their distination and got a perfect fit. It was satisfying. See photo below.

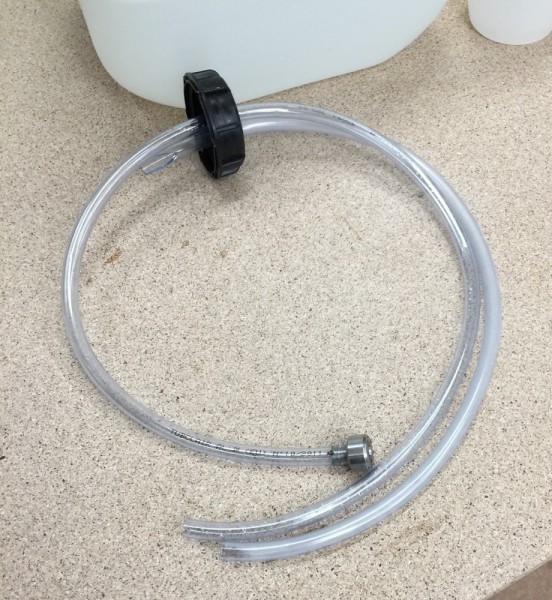

Next problem was, when at sea, how to transfer the water to a bottle. A pump, I thought was to complicated and cumbersome.

I tried to use my non-smoking lungs. It worked to my satisfaction. See photo below.

Below, the tubes I used. The long tube that goes to the bottom of the container has a weight to sink it.

To be continued…

Regards Yrvind.

A NEW MOCKUP

Work with the foreward deckhouse continues. Belov the sides are joined. The brown stoff at the bottom is Tufnaol channels to take the gasket.

After filleting and taping the outside joints the inner edges are given a radieus and is taped, but not before the holes for the windows are cut out.

The edges are not rounded and the deck is not laminated, but it gives an idea of what the finished product will look like.

I decided to upgrade the aft deckhouse so I wisely made a secound mockup and much was gained by that. A bit like an author makes a secound draft.

Symmetry made me get avay with making only only one side. On each side of the foreward end of the deckhouse a ventilator lives. Interference, I say is my biggest problem. Below the deck of the deckhouse is the place of the doradoboxes. They should not interfere with the windows and the windows must be placed very accurately to give the best possible view. The foreward end of the deckhouse slopes a bit down. The dorade channels slope uppward. Water flows downward. This fact helps to separate the the water from the air. The water is collected in a box in the foreward end of the deckhouse. A U-tube lets out water but not air. The air continues backwards where it meets a secound watertrap which also is drained via an U-tube. This Dorade-system has much volume therefore it can swollow much water. Finally the channels passes through the bulkhead to the aft compartment where they go down and traverse the boat.

Becouse I do not have much space I like to keep the ventilation systen in one plane. The trick is to let the air from the starboard ventilater cross at top and the air from the port ventilator cross at the bottom. The pathways is indicated by brown tape.

The diameter of the channels is about 3 cm. Not much you may say, but bigger than my nostrils. This is the heavy weather ventilation systen which I will use when the seas are breaking. Force five and up when the hatches are dogged down. One ventilater takes in air the other lets air out so its a continues air exchange like a birds lung unlike humans who use the same channel for out and in.

Friction in the channels may reduce the airflow to 1 meter per secound, about 2 knots. Still thats gives me 42 liters fresh air a minute enough for an old man resting.

Yes Angélique, when the seas are breaking I will use the safety belt. They not tight so you do not notice them and they do not hinder you getting up.

Next week finds me at the Göteborg Book Fair.

To bee continued…

Regards Yrvind.

VARIUS PHOTOS

Progress is good. Most of the epoxy work under deck is now done. I have started with the foreward deckhouse.

Below are some pictures.

First, me in the deckhouse mockup. Its from here I intend to handle sails and leeboard. I will do that running downwind with the two rudders in breaking position. A rope controlling the rudders runs the inside perifimeter of Ex Lex.

This is the size of all windows. Its mineral glass tempered and heat soaked to resist spontanius granulation.

Prebending the Divinycell with weights where the hatch will be. The inside is laminated.

Cutting the panel to shape.

Details done. The aft storage.

The hatches are bolted down.

The above is a better solution than the one I used on late Yrvind Ten wich consisted of a washer on the screw resting on stainless steel.

Detail of washer. One learns.

This time I am using RG7 Gun Metall to take up the bolt forces. It contains 5 – 7 % lead thus giving very little friction. I could not find material of the right dimension so I bought a bar and sliced it.

Im my bedroom I have laminated in a stainless steel pipe to take the safety belt.

I made several places to fasten the belt. It can be handy to fasten other things to. It do not look beauteiful but it shure is strong.

Fastening poits in the most foreward part of the boat. Part of the anchors and plastic jerrycans can be seen in the background.

To be continued…

Regards Yrvind.

KEEPING THE ANCHORS IN PLACE

When doing the hardware for attaching the anchors the following qualitys where desired.

1. The should be well secured in any weather.

2. When I was going to use the small anchor I did not want to undo the big 15 kilo anshor to reach it.

3. The storage should take as little place as possible and be “friendly”, that is sharp edges should not unnessesarrily hurt me.

4. The anchors center of gravity should be as low as possible and its gyr radius as small as possible.

The following pictures shows how I solved the problem.

The hardware is secured with 47 screws. Each screw is good for about one hundred kilo. The anchors weigh 15 and 6 kilos.

First, the shank of the 15 kilo anchor is secured.

Second. The Shank of the 6 kilo anchor is secured.

Third. The heavy head of the 15 kilo SPADE anchor is secured.

Finally the head of the 6 kilo anchor is secured.

I can remove the shaft and head of the 6 kilo anchor while the 15 kilo is secured.

Information for the landlubber: When at sea, seagoing lashings will be used.

To be continued…

Regards Yrvind.