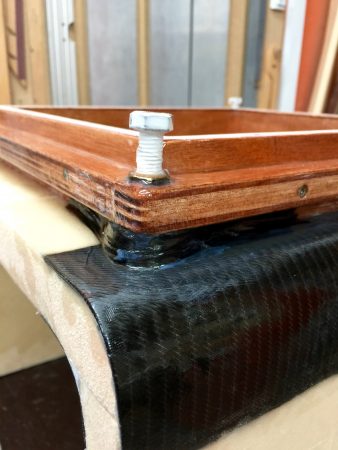

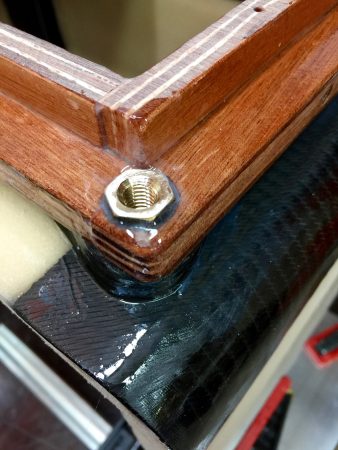

Today I have been working with the bronze plate from Lagermetall Örebro, bent to a fitting curvature by Wevik Maskin AB here in Västervik.

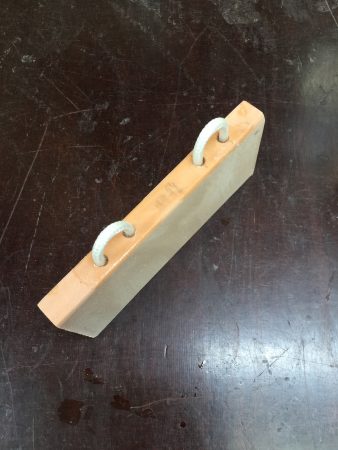

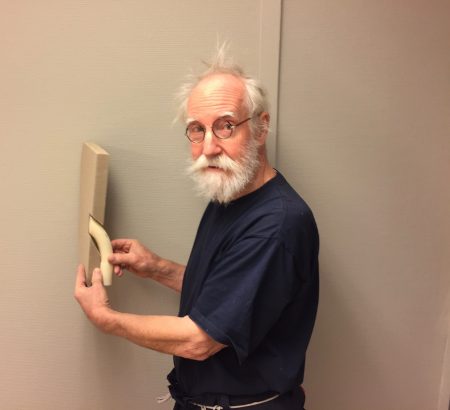

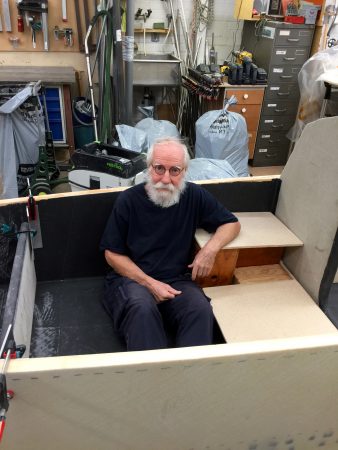

A lot of holes had to be drilled and some tapped. The plate is to big for my drillpress but by using a mighty sharp drill and get support from a box all went well with the holes and the tapping.

It turned out that the plate was heavier than anticipated 138 instead of 127. The extra kilos will do good rounding Cape Horn.

To get the plate in the right place some reshuffling had to be done. The boat had to be put upside down and rolled away, the heavy plate lifted up towards the cealing. The boat had to be rolled back and put in a very precise position below the plate. The finally the plate had to lowered.

All went very well except for the very last correction, then the boat fell over. A bad thing had happend. The bulkheads got damaged but can be fixed without to much weight gain I hope. No use cry over spilled milk. I continued.

To cheer me up the plate fitted itself in the most beatiful way. Only about 9 mm in the back was there a rather wide gap between the plate and the hull. I belive I can do something about it. We will see.

Below some pictures.

To be continued…

Regards Yrvind